Cupro Nickel 70/30 Seamless Pipe

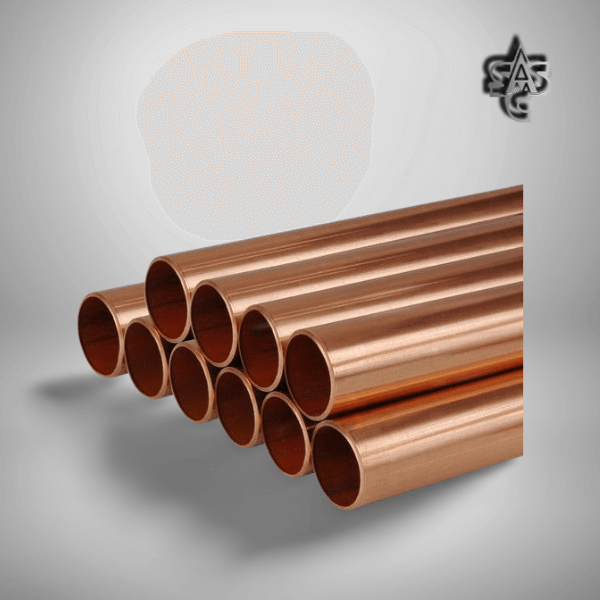

Cupro Nickel Seamless Pipe

Cupro Nickel 70-30 Seamless Pipe, DIN 2.0882 Seamless Tube, ASME SB466 Cu Ni 70-30 Polished Pipe, UNS C71500 Seamless Mirror Finish Pipe, ASTM B466 Cu Ni 70-30 Boiler Pipe.

Parameters, class, measurements, length, width, and diameter are some characteristics that affect Copper-nickel 70/30 Seamless pipes and tubes. Pipes and tubes come in circular, squared, rectangular, and hydraulic shapes. Another important consideration is the pipe and tube length, which should be single or double random. The pipe’s ends have three different finishes: treaded, beveled, and plain. The pipe and tube’s mechanical and physical characteristics are large concentration, relatively high melting, minimum tensile and yield strength, and elongation.

The power generating sector, petrochemicals, gas processing, speciality chemicals, pharmaceuticals, marine equipment, chemical machinery, compressors, heat pumps, and the pulp and paper industry are just a few industries that frequently employ copper-nickel 70/30 pipes and tubes. 70/30 copper and nickel. Most pipes are made to be used in saltwater environments. However, consumers may use them in various sectors since they have considerable strength even in high temperatures. Water filtration units, mechanical lines, saltwater pipelines, marine fire water infrastructure, pumps, cooling systems, and many more devices employ Cu-Ni 70/30 pipes.

About Cupro Nickel 70/30 Seamless Pipe

Properties of Copper Nickel Cu-Ni 70/30 pipes:

The UNS C71500 Cu Ni Seamless Pipes‘ ability to be malleable and more robust than pure copper grades is made possible by including nickel. Copper is a material that is simple to weld. Iron and manganese are added to the Pipes material to facilitate simple welding. Cupronickel pipes come in various grades and are utilised by many industries. A variant of the 70/30 material used primarily on marine and ocean applications is the C71500 Pipe. Copper nickel pipes can be welded or utilized in seamless applications. When compared to other comparable alloys, including copper-aluminium alloys, it is alleged to be more costly. Power stations, refineries, and the defence sector all employ Cu-Ni 70/30 pipes.

Characteristics of Copper Nickel Cu-Ni 70/30 pipes:

These pipes are capable of welding without needing any materials and may form in a cold temper. Pipes and tubes are excellent for demanding applications because of all of these characteristics. While welded pipes are more robust, seamless pipes are better for applications that need accuracy. The plumbing in boats and marine systems might employ these pipes. The material is recommended in boats, ships, and other maritime equipment to be clean because it prevents biofouling, a process that gathers living organisms. One of the most popular types of cupro nickel pipes is the pipes. The ASTM B466 Copper Nickel 70/30 Pipes are utilized in situations where both corrosion resistance and strength are essential. Boilers, condensers, and heat exchangers all need pipes.

Specification Of Cupro Nickel 70/30 Seamless Pipe

| Copper-Nickel Seamless Pipes Specifications | ASTM B466, B467 / ASME SB466, SB467 |

| Dimensional specification | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

| Copper-Nickel Seamless Pipe Size | 1 / 8" NB - 24" NB |

| Copper-Nickel Welded Pipe Size | 1 / 8" NB - 24" NB |

| Outside Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Tubes available Ex-stock |

| Copper Nickel Pipes Manufacturing Shapes | Hydraulic, Round, Rectangle, Square, Hex, Honed |

| Manufacturing Techniques | Normalized & as Rolled |

| Copper Nickel Pipe Schedule Thickness Range | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Copper Nickel Pipes End Types | Plain End, Beveled End, Treaded One End, TBE (Treaded Both Ends) |

| Value Added Services | Cutting, Beveling, Polishing, Threading, Destructive, Non Destructive, Ultrasonic Testing |

| Inspection and Test Reports | EN 10204 3.1, Mill Test Certificates, Chemical Reports, PMI Test Reports, Mechanical Reports, Third Party Inspection, NABL Approved Lab, Visual Inspection, Destructive Test and Non Destructive Test Reports |

| Heat Treatment | Normalized, Normalized & Tempered |

| Packing of Copper Nickel Pipes | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials | Sizes and Specifications other than above can be on request |

Equivalent Grades Cupro Nickel 70/30 Seamless Pipe

| STANDARD | WERKSTOFF NR. | UNS |

| Copper Nickel 70/30 | 2.0882 | C71500 |

Chemical Composition Cupro Nickel 70/30 Seamless Pipe

| Grade | Cu | Mn | Pb | Ni | Fe | Zn |

| Cu-Ni 70-30 | 65.0 min | 1 max | .05 max | 29-33 | 0.4-1.0 | 1 max |

Mechanical Properties Cupro Nickel 70/30 Seamless Pipe

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Copper Nickel 70-30 | 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

Dimensions Of Cupro Nickel 70/30 Seamless Pipe

cupro Nickel Seamless Pipe Dimensions Chart :

| Nominal Pipe Size | Outside Diameter (mm) | Nominal Wall Thickness Schedule | |||||||||||||||||

| NPS | DN | OD | SCH5s | SCHl0s | SCH 10 | SCH 20 | SCH 30 | SCH40s | SCH STD | SCH 40 | SCH 60 | SCH80s | SCH XS | SCH 80 | SCH 100 | SCH 120 | SCH 140 | SCH 160 | SCH XXS |

| 1/8 | 6 | 10.3 | 1.24 | 1.73 | 1.73 | 1.73 | 2.41 | 2.41 | 2.41 | ||||||||||

| 1/4 | 8 | 13.7 | 1.65 | 2.24 | 2.24 | 2.24 | 3.02 | 3.02 | 3.02 | ||||||||||

| 3/8 | 10 | 17.1 | 1.65 | 2.31 | 2,31 | 2.31 | 3.20 | 3.20 | 3.20 | ||||||||||

| 1/2 | 15 | 21.3 | 1.65 | 2.11 | 2.77 | 2.77 | 2.77 | 3.73 | 3.73 | 3.73 | 4.78 | 7.47 | |||||||

| 3/4 | 20 | 26.7 | 1.65 | 2.11 | 2.87 | 2.87 | 2.87 | 3.91 | 3.91 | 3.91 | 5.56 | 7.82 | |||||||

| 1 | 25 | 33.4 | 1.65 | 2.77 | 3.38 | 3.38 | 3.38 | 4.55 | 4.55 | 4.55 | 6.35 | 9.09 | |||||||

| 1 1/4 | 32 | 42.2 | 1.65 | 2.77 | 3.56 | 3.56 | 3,56 | 4.85 | 4.85 | 4.85 | 6.35 | 9.70 | |||||||

| 1 1/2 | 40 | 48.3 | 1.65 | 2.77 | 3.68 | 3.68 | 3.68 | 5.08 | 5.08 | 5.08 | 7.14 | 10.15 | |||||||

| 2 | 50 | 60.3 | 1.65 | 2.77 | 3.91 | 3.91 | 3.91 | 5.54 | 5.54 | 5.54 | 8.74 | 11.07 | |||||||

| 2 1/2 | 65 | 73 | 2.11 | 3.05 | 5.16 | 5.16 | 5.16 | 7.01 | 7.01 | 7.01 | 9.53 | 14.02 | |||||||

| 3 | 80 | 88.9 | 2.11 | 3.05 | 5.49 | 5.49 | 5.49 | 7.62 | 7.62 | 7.62 | 11.13 | 15.24 | |||||||

| 3 1/2 | 90 | 101.6 | 2.11 | 3.05 | 5.74 | 5.74 | 5.74 | 8.08 | 8.08 | 8.08 | |||||||||

| 4 | 100 | 114.3 | 2.11 | 3.05 | 6.02 | 6.02 | 6.02 | 8.56 | 8.56 | 8.56 | 11.13 | 13.49 | 17.12 | ||||||

| 5 | 125 | 141.3 | 2.77 | 3.40 | 6.55 | 6.55 | 6.55 | 9.53 | 9,53 | 9.53 | 12.70 | 15.88 | 19.05 | ||||||

| 6 | 150 | 168.3 | 2.77 | 3.40 | 7.11 | 7.11 | 7.11 | 10.97 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | ||||||

| 8 | 200 | 219.1 | 2.77 | 3.76 | 6.35 | 7.04 | 8.18 | 8.18 | 8.18 | 10.31 | 12.70 | 12.70 | 12.70 | 15.09 | 18.26 | 20.62 | 23.01 | 22.23 | |

| 10 | 250 | 273.1 | 3.40 | 4.19 | 6.35 | 7.80 | 9.27 | 9.27 | 9.27 | 12.70 | 12.70 | 12.70 | 15.09 | 18.26 | 21.44 | 25.40 | 28.58 | 25.40 | |

| 12 | 300 | 323.9 | 3.96 | 4.57 | 6.35 | 8.38 | 9.53 | 9.53 | 10.31 | 14.27 | 12.70 | 12.70 | 17.48 | 21.44 | 25.40 | 28.58 | 33.32 | 25.40 | |

| 14 | 350 | 355.6 | 3.96 | 4.78 | 6.35 | 7.92 | 9.53 | 9.53 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |||

| 16 | 400 | 406.4 | 4.19 | 4.78 | 6.35 | 7.92 | 9.53 | 9.53 | 12.70 | i6.66 | 12.70 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | |||

| 18 | 450 | 457.2 | 4.19 | 4.78 | 6.35 | 7.92 | 11.13 | 9.53 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34.93 | 39,67 | 45.24 | |||

| 20 | 500 | 508 | 4.78 | 5.54 | 6.35 | 9.53 | 12.70 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 | |||

| 22 | 559 | 4.78 | 5.54 | 6.35 | 9.53 | 12.70 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | |||||

| 24 | 600 | 610 | 5.54 | 6.35 | 6.35 | 9.53 | 14.27 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |||

| 26 | 660 | 7.92 | 12.70 | 9.53 | 12.70 | ||||||||||||||

| 28 | 700 | 711 | 7.92 | 12.70 | 15.88 | 9.53 | 12.70 | ||||||||||||

| 30 | 762 | 6.35 | 7.92 | 7.92 | 12.70 | 15.88 | 9.53 | 12.70 | |||||||||||

| 32 | 800 | 813 | 7.92 | 12.70 | 15.88 | 9.53 | 17.48 | 12.70 | |||||||||||

| 34 | 884 | 7.92 | 12.70 | 15.88 | 9.53 | 17.48 | 12.70 | ||||||||||||

| 36 | 900 | 914 | 7.92 | 12.70 | 15.88 | 9.53 | 19.05 | 12.70 | |||||||||||

| 38 | 965 | 9.53 | 12.70 | ||||||||||||||||

| 40 | 1000 | 1016 | 9.53 | 12.70 | |||||||||||||||

| 42 | 1067 | 12.70 | 15.88 | 9.53 | 19.05 | 12.70 | |||||||||||||

| 44 | 1100 | 1118 | 9.53 | 12.70 | |||||||||||||||

| 46 | 1168 | 9.53 | 12.70 | ||||||||||||||||

| 48 | 1200 | 1219 | 9.53 | 12.70 | |||||||||||||||

| 52 | 1321 | ||||||||||||||||||

| 56 | 1422 | ||||||||||||||||||

| 60 | 1524 | ||||||||||||||||||

Different Types Of Cupro Nickel 70/30 Seamless Pipe

Different Types Of seamless Pipe

- Cupro Nickel 70-30 Seamless Pipe

- UNS C71500 Seamless Mirror Finish Pipe

- DIN 2.0882 Seamless tube

- ASTM B466 Cu Ni 70-30 Boiler Pipe

- ASME SB466 Cu Ni 70-30 Polished pipe

- Cu Ni 70-30 Seamless Tube

- UNS C71500 Seamless Mirror Finish Tubes

- DIN 2.0882 Seamless Pipes

- B466 ASTM Cu Ni 70-30 Boiler Tubes

- SB466 ASME Cu Ni 70-30 Polished Tubes

Application of Cupro Nickel 70/30 Seamless Pipe

Testing of Cupro Nickel 70/30 Seamless Pipe

Packing of Cupro Nickel 70/30 Seamless Pipe

Destination Of Cupro Nickel 70/30 Seamless Pipe

- City We Deliver

- Country We Export

- People Also Search