ASTM F467 Nut

ASTM Standard Nut

ASME SF467 Grade T Nut, Grade Acorn Nut, Grade F467 Nyloc Nut, ASTM F467 Hex Head Nut, ASME SF467 Grade Eye Nut, F467 Grade Wing Nut.

The ASTM F467 specification covers nuts made of brass, naval brass, aluminum bronze, and silicon bronze; the ASTM f467 nuts are a part of this specification. These ASTM F467m nuts are available from Shree Ashapura Steel, a reputable producer and supplier of fasteners in a wide range of sizes and dimensions. When making these nuts, a variety of alloys, including grades 260, 464, 630, and 655, are utilized. These nuts can be made from any of these.

There are a variety of shapes, and each form is helpful for a specific type of application. Because of the ease with which they may be applied with various tools and their high geometric strength, ASTM F467 Hex Nuts are among the most widely used nuts in multiple industries.

About ASTM F467 Nut

There are also heavy hex nuts in addition to the regular hex nuts. In accordance with this specification, the copper content of the ASTM F467 Wing Nuts can range anywhere from 59% in the case of the naval brass material to 94% in the case of the silicon bronze material. Due to the high amount of copper present, the ASTM F467 Acorn Nuts and other varieties are able to tolerate high levels of acidic corrosion.

Because of this property, the nuts are an excellent choice for acid processing as well as other chemical applications and instruments. In addition to copper, the ASTM F467 Square Nuts, classified as grades 630 and 655, contains 1.5% manganese. Additionally, the square nuts can be utilized for various application types due to the space available for nut tightening. Copper makes up 78% of the composition of the aluminum bronze nuts, which also contain 9% to 11% aluminum.

Because of this, the nuts are superior to other kinds in both their strength and their resistance to corrosion. We are a significant producer and supplier, and one of the products we make is a wide variety of nuts, including the ASTM F467 Coupling Nuts and other items that fall under the ASTM F467 specification. Feel free to get in touch with us at any time for further information and prices.

Specification Of ASTM F467 Nut

| Standards | Designation |

| ASTM | F467 |

| Astm F467 Nuts Delivery time | custom product will according to special requirement, Regular product is about 7-15 days |

| ASTM F467 Nuts Coatings | Cadmium, Black Oxide, Teflon, Galvanized, Zinc, Xylan, Otders Upon Request |

| Astm F467 Nuts Dimensions | ASME B18.3, B18.2.1 |

| Melt Origin | Soutd America/East Europe/Japan/Korea |

| Product Origin | Made in India |

| Astm F467 Nuts Certification | Dual Certified As per ASME & ASTM Codes |

| Additional Certifications | Merkblatt AD 2000 W2 Certified,PED 97/23/EC Certified |

| Mandatory Requirements | Free from Radioactive & Mercury Contamination |

| Additional Requirements | NACE MR0175 / MR0103 /ISO 15156 Compliance |

| Astm F467 Nuts Samples | Yes |

| Payment Terms | Western Union, T/T, Paypal, Trade Assurance 30% deposit & balance before shipping or L/C |

Chemical Composition ASTM F467 Nut

| UNS Designation | Alloy | General Name | Aluminum | Copper, min | Iron, max | Manganese, max | Nickel, max | Phosphorus | Silicon | Zinc, maxA | Lead, max | Tin |

| C11000 | 110 | ETP Copper | — | 99.9 | — | — | — | — | — | — | — | — |

| C26000 | 260 | Brass | — | 68.5 – 71.5 | 0.05 | — | — | — | — | balance | 0.07 | — |

| C27000 | 270 | Brass | — | 63.0 – 68.5 | 0.07 | — | — | — | — | balance | 0.10 | — |

| C46200 | 462 | Naval Brass | — | 62.0 – 65.0 | 0.10 | — | — | — | — | balance | 0.20 | 0.50 – 1.00 |

| C46400 | 464 | Naval Brass | — | 59.0 – 62.0 | 0.10 | — | — | — | — | balance | 0.20 | 0.50 – 1.00 |

| C51000 | 510 | Phosphor Bronze | — | balanceA | 0.10 | — | — | 0.03 – 0.35 | — | 0.30 | 0.05 | 4.20 – 5.80 |

| C61300 | 613 | Aluminum Bronze | 6.0 – 7.5 | B | 2.0 – 3.0 | 0.10 | 0.15C | 0.015 | 0.10 | 0.05 | 0.01 | 0.20 – 0.50 |

| C61400 | 614 | Aluminum Bronze | 6.0 – 8.0 | 88.0D | 1.5 – 3.5 | 1.00 | — | — | — | — | — | — |

| C63000 | 630 | Aluminum Bronze | 9.0 – 11.0 | 78.0D | 2.0 – 4.0 | 1.50 | 4.0 – 5.5 | — | 0.25 max | — | — | 0.20 max |

| C64200 | 642 | Aluminum Silicon Bronze | 6.3 – 7.6 | 88.65D | 0.30 | 0.10 | 0.25 | 1.50 – 2.20E | 0.50 | 0.05 | 0.20 max | |

| C65100 | 651 | Silicon Bronze | — | 96.0D | 0.80 | 0.70 | — | — | 0.8 – 2.0 | 1.50 | 0.05 | — |

| C65500 | 655 | Silicon Bronze | — | 94.8D | 0.80 | 1.50 | 0.60 | — | 2.8 – 3.8 | 1.50 | 0.05 | — |

| C66100 | 661 | Silicon Bronze | 0.25 max | 94.0D | 0.25 | 1.50 | — | — | 2.8 – 3.5 | 1.50 | 0.20 – 0.80 | — |

| C67500 | 675 | Manganese Bronze | — | 57.0 – 60.0 | 0.8 – 2.0 | 0.05 – 0.50 | — | — | — | balance | 0.20 | 0.50 – 1.50 |

| C71000 | 710 | Cupro Nickel | — | 74.0D | 0.60 | 1.00 | 19.0 – 23.0C | — | 1.00 | 0.05 | — | |

| C71500 | 715 | Cupro Nickel | — | 65.0D | 0.40 – 0.70 | 1.00 | 29.0 – 33.0C | — | — | 1.00 | 0.05 | — |

Mechanical Properties ASTM F467 Nut

| Alloy | Mechanical Property Marking | Nominal Thread Diameter, inch | HardnessA | Proof Stress, min, ksi |

| Cu 110 | F 467A | all | 65 HRF | 30 |

| Cu 260 | F 467AB | all | 55 HRF | 60 |

| Cu 270 | F 467B | all | 55 HRF | 60 |

| Cu 462 | F 467C | all | 65 HRB | 50 |

| Cu 464 | F 467D | all | 55 HRB | 50 |

| Cu 510 | F 467E | all | 60 HRB | 60 |

| Cu 613 | F 467F | all | 70 HRB | 80 |

| Cu 614 | F 467G | all | 70 HRB | 75 |

| Cu 630 | F 467H | all | 85 HRB | 100 |

| Cu 642 | F 467J | all | 75 HRB | 75 |

| Cu 651 | F 467K | all | 75 HRB | 70 |

| Cu 655 | F 467L | all | 60 HRB | 50 |

| Cu 661 | F 467M | all | 75 HRB | 70 |

| Cu 675 | F 467N | all | 60 HRB | 55 |

| Cu 710 | F 467P | all | 50 HRB | 45 |

| Cu 715 | F 467R | all | 60 HRB | 55 |

| Ni 59 Grade 1 | F467FN | all | 21 HRC | 120 |

| Ni 59 Grade 2 | F467GN | all | 23 HRC | 135 |

| Ni 59 Grade 3 | F467HN | all | 25 HRC | 160 |

| Ni 59 Grade 4 | F467JN | all | 80 HRB | 100 |

| NI 335 | F 467S | all | 20 HRC | 115 |

| Ni 276 | F 467T | all | 20 HRC | 110 |

| Ni 400 | F 467U | all | 75 HRB | 80 |

| Ni 405 | F 467V | all | 60 HRB | 70 |

| Ni 500 | F 467W | all | 24 HRC | 130 |

| Ni 625 | F 467AC | all | 85 HRB – 35 HRC | 60 |

| Ni 686 Grade 1 | F 467BN | all | 21 HRC | 120 |

| Ni 686 Grade 2 | F 467CN | all | 23 HRC | 135 |

| Ni 686 Grade 3 | F 467DN | all | 25 HRC | 160 |

| Ni 686 Grade 4 | F 467EN | all | 65 HRB – 25 HRC | 100 |

| Al 2024 – T4B | F 467X | all | 70 HRB | 55 |

| Al 6061 – T6 | F 467Y | all | 40 HRB | 40 |

| Al 6262 – T9 | F 467Z | all | 60 HRB | 52 |

| Ti 1 | F 467AT | all | 140 HV | 40 |

| Ti 2 | F 467BT | all | 150 HV | 55 |

| Ti 4 | F 467CT | all | 200 HV | 85 |

| Ti 5 | F 467DT | all | 30 HRC | 135 |

| Ti 7 | F 467ET | all | 160 HV | 55 |

| Ti 19 | F 467FT | all | 24 HRC | 120 |

| Ti 23 | F 467GT | all | 25 HRC | 125 |

| Ti-5-1-1-1 | F 467AHT | all | 24 HRC | 105 |

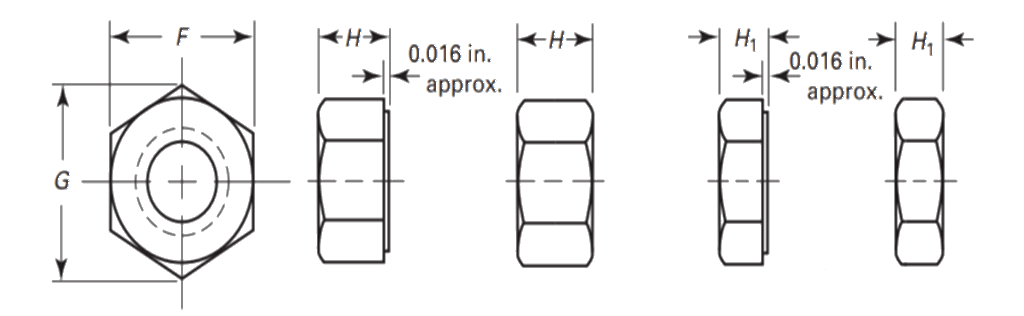

Dimensions Of ASTM F467 Nut

Stainless Steel Nuts Dimensions :

| Nominal Size inch | Basic Major Diameter of Thread | Width Across Flats, F | Width Across Corners, G | Thickness Heavy Hex Nuts, H | Thickness Heavy Hex Jam Nuts, H1 | Maximum Runout of Bearing Surface to Thread Axis, FIM |

|||||||||

| Heavy HEX NUTS | Heavy Hex Jam Nuts |

||||||||||||||

| Specified Proof load | |||||||||||||||

| Basic inch | Min. | Max | Min. | Max | Basic inch | Min. | Max | Basic inch | Min. | Max | Up to 150,000 psi | 150,000 psi and Greater | All Strength Levels |

||

| 1/4 | 0.2500 | 1/2 | 0.488 | 0.500 | 0.556 | 0.577 | 15/64 | 0.218 | 0.250 | 11/64 | 0.156 | 0.188 | 0.017 | 0.011 | 0.017 |

| 5/16 | 0.3125 | 9/16 | 0.546 | 0.562 | 0.622 | 0.650 | 19/64 | 0.280 | 0.314 | 13/64 | 0.186 | 0.220 | 0.020 | 0.012 | 0.020 |

| 3/8 | 0.3750 | 11/16 | 0.669 | 0.688 | 0.763 | 0.794 | 23/64 | 0.341 | 0.377 | 15/64 | 0.216 | 0.252 | 0.021 | 0.014 | 0.021 |

| 7/16 | 0.4375 | 3/4 | 0.728 | 0.750 | 0.830 | 0.866 | 27/64 | 0.403 | 0.441 | 17/64 | 0.247 | 0.285 | 0.022 | 0.015 | 0.022 |

| 1/2 | 0.5000 | 7/8 | 0.850 | 0.875 | 0.969 | 1.010 | 31/64 | 0.464 | 0.504 | 19/64 | 0.277 | 0.317 | 0.023 | 0.016 | 0.023 |

| 9/16 | 0.5625 | 15/16 | 0.909 | 0.938 | 1.037 | 1.083 | 35/64 | 0.526 | 0.568 | 21/64 | 0.307 | 0.349 | 0.024 | 0.017 | 0.024 |

| 5/8 | 0.6250 | 1 1/16 | 1.031 | 1.062 | 1.175 | 1.227 | 39/64 | 0.587 | 0.631 | 23/64 | 0.337 | 0.381 | 0.025 | 0.018 | 0.025 |

| 3/4 | 0.7500 | 1 1/4 | 1.212 | 1.250 | 1.382 | 1.443 | 47/64 | 0.710 | 0.758 | 27/64 | 0.398 | 0.446 | 0.027 | 0.020 | 0.027 |

| 7/8 | 0.8750 | 1 7/16 | 1.394 | 1.438 | 1.589 | 1.660 | 55/64 | 0.833 | 0.885 | 31/64 | 0.458 | 0.510 | 0.029 | 0.022 | 0.029 |

| 1 | 1.0000 | 1 5/8 | 1.575 | 1.625 | 1.796 | 1.876 | 63/64 | 0.956 | 1.012 | 35/64 | 0.519 | 0.575 | 0.031 | 0.024 | 0.031 |

| 1 1/8 | 1.1250 | 1 13/16 | 1.756 | 1.812 | 2.002 | 2.093 | 1 7/64 | 1.079 | 1.139 | 39/64 | 0.579 | 0.639 | 0.033 | 0.027 | 0.033 |

| 1 1/4 | 1.2500 | 2 | 1.938 | 2.000 | 2.209 | 2.309 | 1 7/32 | 1.187 | 1.251 | 23/32 | 0.687 | 0.751 | 0.035 | 0.030 | 0.035 |

| 1 3/8 | 1.3750 | 2 3/16 | 2.119 | 2.188 | 2.416 | 2.526 | 1 11/32 | 1.310 | 1.378 | 25/32 | 0.747 | 0.815 | 0.038 | 0.033 | 0.038 |

| 1 1/2 | 1.5000 | 2 3/8 | 2.300 | 2.375 | 2.622 | 2.742 | 1 15/32 | 1.433 | 1.505 | 27/32 | 0.808 | 0.880 | 0.041 | 0.036 | 0.041 |

| 1 5/8 | 1.6250 | 2 9/16 | 2.481 | 2.562 | 2.828 | 2.959 | 1 19/32 | 1.556 | 1.632 | 29/32 | 0.868 | 0.944 | 0.044 | 0.038 | 0.044 |

| 1 3/4 | 1.7500 | 2 3/4 | 2.662 | 2.750 | 3.035 | 3.175 | 1 23/32 | 1.679 | 1.759 | 31/32 | 0.929 | 1.009 | 0.048 | 0.041 | 0.048 |

| 1 7/8 | 1.8750 | 2 15/16 | 2.844 | 2.938 | 3.242 | 3.392 | 1 27/32 | 1.802 | 1.886 | 1 1/32 | 0.989 | 1.073 | 0.051 | 0.044 | 0.051 |

| 2 | 2.0000 | 3 1/8 | 3.025 | 3.125 | 3.449 | 3.608 | 1 31/32 | 1.925 | 2.013 | 1 3/32 | 1.050 | 1.138 | 0.055 | 0.047 | 0.055 |

| 2 1/4 | 2.2500 | 3 1/2 | 3.388 | 3.500 | 3.862 | 4.041 | 2 13/64 | 2.155 | 2.251 | 1 13/64 | 1.155 | 1.251 | 0.061 | 0.052 | 0.061 |

| 2 1/2 | 2.5000 | 3 7/8 | 3.750 | 3.875 | 4.275 | 4.474 | 2 29/64 | 2.401 | 2.505 | 1 29/64 | 1.401 | 1.505 | 0.068 | 0.058 | 0.068 |

| 2 3/4 | 2.7500 | 4 1/4 | 4.112 | 4.250 | 4.688 | 4.907 | 2 45/64 | 2.647 | 2.759 | 1 37/64 | 1.522 | 1.634 | 0.074 | 0.064 | 0.074 |

| 3 | 3.0000 | 4 5/8 | 4.475 | 4.625 | 5.102 | 5.340 | 2 61/64 | 2.893 | 3.013 | 1 45/64 | 1.643 | 1.763 | 0.081 | 0.070 | 0.081 |

| 3 1/4 | 3.2500 | 5 | 4.838 | 5.000 | 5.515 | 5.774 | 3 3/16 | 3.124 | 3.252 | 1 13/16 | 1.748 | 1.876 | 0.087 | 0.075 | 0.087 |

| 3 1/2 | 3.5000 | 5 3/8 | 5.200 | 5.375 | 5.928 | 6.207 | 3 7/16 | 3.370 | 3.506 | 1 15/16 | 1.870 | 2.006 | 0.094 | 0.081 | 0.094 |

| 3 3/4 | 3.7500 | 5 3/4 | 5.562 | 5.750 | 6.341 | 6.640 | 3 11/16 | 3.616 | 3.760 | 2 1/16 | 1.990 | 2.134 | 0.100 | 0.087 | 0.100 |

| 4 | 4.0000 | 6 1/8 | 5.925 | 6.125 | 6.755 | 7.073 | 3 15/16 | 3.862 | 4.014 | 2 3/16 | 2.112 | 2.264 | 0.107 | 0.093 | 0.107 |

Different Types Of ASTM F467 Nut

Different Types Of Bolts

- ASTM F467 Hex Head Nut

- ASME SF467 T Nut

- F467 Grade Nyloc Nut

- SF467 Grade Wing Nut

- F467 Grade Acorn Nut

- ASME SF467 Grade Hex Nut

- F467 Grade SF467 Eye Nut

- SF467 ASTM Square Nut

Application of ASTM F467 Nut

Testing of ASTM F467 Nut

Packing of ASTM F467 Nut

Destination Of ASTM F467 Nut

- City We Deliver

- Country We Export

- People Also Search

Grade F467 Nyloc Nut Supplier in Chennai, Grade F467 Eye Nut Supplier in Hyderabad, ASTM F467 Hex Head Nut Manufacturer in Ahmedabad, Grade Hex Nut Exporter in Pimpri-Chinchwad, ASME SF467 Grade Heavy Hex Nut Stockist in Coimbatore, Grade Square Nut Exporter in Bangalore, Grade Acorn Nut Manufacturer in Jamnagar, ASME SF467 Grade T Nut Stockist in Pune.

Grade F467 Eye Nut Supplier in Malaysia, Grade F467 Nyloc Nut Supplier in Qatar, Grade Hex Nut Manufacturer in Nigeria, ASTM F467 Square Nut Manufacturer in UAE, ASME SF467 Grade T Nut Stockist in Indonesia, ASME SF467 Grade Acorn Nut Stockist in Dubai, Grade Acorn Nut Exporter in Argentina, ASME SF467 Grade T Nut Stockist in South Africa, Grade F467 Wing Nut Supplier in Brazil, Grade Wing Nut Exporter in Saudi Arabia, Grade Acorn Nut Manufacturer in Singapore, Grade Hex Head Nut Exporter in Tanzania.

Grade F467 T Nut Grade Chart, Grade Square Nut at Factory Price, ASTM F467 Nyloc Nut Price List, Grade Acorn Nut Price Per Kg, ASME SF467 Grade Eye Nut at Factory Price, ASME SF467 Grade Wing Nut Weight Chart, Grade F467 Eye Nut Weight Calculator, ASME SF467 Grade Hex Head Nut Catalogue, ASTM F467 Wing Nut Specification, Grade Hex Nut Price List in India.