Cupro Nickel 70/30 Bolt

70-30 Copper Nickel U Bolt, ASME SB151 Cu Ni 70-30 Hex Bolt, Grade 70-30 Eye Bolt, ASTM B151 Cu Ni 70/30 Stud Bolt, , Cupro Nickel 70-30 Hex Head Bolt, 70/30 Copper Nickel Anchor Bolt, UNS C71500 Flange Head Bolt, DIN 2.0882 Allen Bolt.

What are Cupro Nickel 70/30 Bolts?

90% Copper and 10% Nickel make up the material known as cupronickel 70/30. The alloy’s overall characteristics are improved by the addition of iron and manganese present. Fasteners of alloy 70/30 are renowned for resisting hydrogen embrittlement and maintaining their mechanical integrity even at shallow temperatures.

Due to their flexibility and strength, Cupro Nickel 70/30 Bolts are used in the maritime, offshore, shipbuilding, chemical, petrochemical and construction industries. At higher temperatures, the Copper Nickel 70/30 Hex Bolts maintain excellent quality and durability. Exceptional oxidation resistance is provided by these bolts in moist air and steam.

Properties of Cupro Nickel 70/30 Bolts:

Grade 70-30 Square Bolts, have an exceptional tolerance to general rust and crevice corrosion cracking due to their low iron content, which ranges from 0.5% to 0.1%. This condition makes them perfect for the maritime or industrial sectors. Cu-Ni, 70/30 Square Nuts, is used in coinage and power plants, naval exploration equipment, and vehicle parts. Cupro Nickel 70/30 Eye Bolts have single-stage alpha structures because nickel is soluble in copper. Due to this, 70/30 Cu-Ni Eye Nuts are frequently used in propellers and crankshafts, pipes, heat exchangers, and capacitors in seawater systems.

Major features of ASTM B151 Copper Nickel 70/30 Head Hex bolts include corrosion rate, inherent resistance to representing a significant, decent elastic properties, excellent damage tolerance when subjected to heat, temperature rise and development characteristics appropriate for heat exchange and compressors, increased thermal conductivity and reliability at cryogenic temperatures, and good tensile strength.

About Cupro Nickel 70/30 Bolt

Characteristics of Cupro Nickel 70/30 Bolts:

- The specification of DIN 2.0882 Stud Bolt is ASTM B 151 and ASME SB 151.

- The length of UNS C71500 Heavy Hex Nut ranges from 3 mm to 70/30mm.

- The size of Cupro Nickel 70/30 Threaded Rod varies from M03 to M56.

Applications of Cupro Nickel 70/30 Bolts:

The following are practical uses of cupronickel C276 Bolts:

- Fuselages of yachts and ships, saltwater cooling, sewage and sediment, sanitation, fire rescue, inert gas, and mechanical and pneumatic chiller equipment are all parts of shipbuilding and ship maintenance.

- Desalination facilities: such applications include evaporator tubing, heat removal and recovery, and brine heaters.

- Other applications are Structures and splashing zone sheathings for offshore oil and natural gas platforms, processing vessels, and FPSOs.

- Power generation: high-pressure pre-heaters, cooling coils, auxiliary cooling systems, and steam turbine condensers in fossil and nuclear power plants.

- Concentrator and heat exchanger pipes, tube sheets, pipelines, highly pressurized devices, fittings, motors, and water boxes are some of the parts of a seawater system.

- Applications involving cryogenics employ cupronickel. It is ideal for heat exchangers in cryogenic facilities and low-temperature storage and processing devices due to its combination of high elasticity preservation and thermal conductivity at shallow temperatures.

Specification Of Cupro Nickel 70/30 Bolt

| Specifications | ASTM B151 / ASME SB151 and DIN, ISO ,JIS ,GB, IS, BS, ASTM and all International Standards |

| Size | M3 - M100 | 3/6″ - 4″ | Custom Sizes |

| Length | 3 mm - 200 mm | Custom Sizes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads and UNF, BSW, BSF, METRIC, UNC, or as required |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Head | Hex, Square, Round, Hex flange, Flat, T-head & Triangular etc. |

| Neck type | Hex, Square, Triangular, Oval & Knurled etc. |

| Manufacturing Process | Passivation /plain, Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing. |

| Surface Coating | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Packing | IN BULK: carton, pallet, Small Boxes or customer request |

| Test Certificate | As per EN 10204 / 3.1 Manufacturer Test Certificate, PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Delivery time | Regular product : 7-15 days, Custom product : 2-4 weeks |

Equivalent Grades Cupro Nickel 70/30 Bolt

| STANDARD | UNS | WNR. |

| Copper Nickel 70/30 | C71500 | 2.0882 |

Chemical Composition Cupro Nickel 70/30 Bolt

| Grade | Cu | Mn | Pb | Ni | Fe | Zn |

| Cu-Ni 70-30 | 65.0 min | 1 max | .05 max | 29-33 | 0.4-1.0 | 1 max |

Mechanical Properties Cupro Nickel 70/30 Bolt

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Cupro Nickel 70/30 | 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

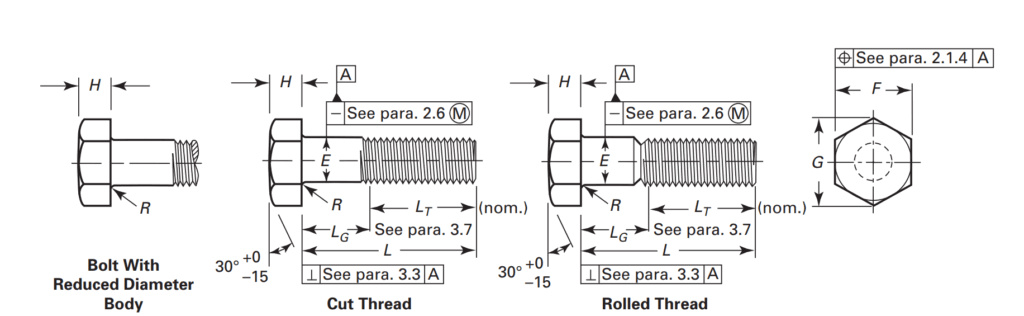

Dimensions Of Cupro Nickel 70/30 Bolt

Cupro Nickel Bolts Dimensions Chart :

| Nominal Size or Basic Product Diameter | Full-Size Body Diameter, E | Width Across Flats, F | Width Across Corners, G | Head Height, H Basic | Radius of Fillet, R | Nominal Thread Length for Bolt Lengths, LT |

|||||||||

| inch | mm | Max | Min | Basic inch | Max | Min | Max | Min | Basic inch | Max | Min | Max | Min | 6 in. and Shoter | Over 6 in. |

| 1⁄4 | 0.25 | 0.26 | 0.237 | 7⁄16 | 0.438 | 0.425 | 0.505 | 0.484 | 11⁄64 | 0.188 | 0.15 | 0.03 | 0.01 | 0.75 | 1 |

| 5⁄16 | 0.3125 | 0.324 | 0.298 | 1⁄2 | 0.5 | 0.484 | 0.577 | 0.552 | 7⁄32 | 0.235 | 0.195 | 0.03 | 0.01 | 0.875 | 1.125 |

| 3⁄8 | 0.375 | 0.388 | 0.36 | 9⁄16 | 0.562 | 0.544 | 0.65 | 0.62 | 1⁄4 | 0.268 | 0.226 | 0.03 | 0.01 | 1 | 1.25 |

| 7⁄16 | 0.4375 | 0.452 | 0.421 | 5⁄8 | 0.625 | 0.603 | 0.722 | 0.687 | 19⁄64 | 0.316 | 0.272 | 0.03 | 0.01 | 1.125 | 1.375 |

| 1⁄2 | 0.5 | 0.515 | 0.482 | 3⁄4 | 0.75 | 0.725 | 0.866 | 0.826 | 11⁄32 | 0.364 | 0.302 | 0.03 | 0.01 | 1.25 | 1.5 |

| 5⁄8 | 0.625 | 0.642 | 0.605 | 15⁄16 | 0.938 | 0.906 | 1.083 | 1.033 | 27⁄64 | 0.444 | 0.378 | 0.06 | 0.02 | 1.5 | 1.75 |

| 3⁄4 | 0.75 | 0.768 | 0.729 | 11⁄8 | 1.125 | 1.088 | 1.299 | 1.24 | 1⁄2 | 0.524 | 0.455 | 0.06 | 0.02 | 1.75 | 2 |

| 7⁄8 | 0.875 | 0.895 | 0.852 | 1 5⁄16 | 1.312 | 1.269 | 1.516 | 1.447 | 37⁄64 | 0.604 | 0.531 | 0.06 | 0.02 | 2 | 2.25 |

| 1 | 1 | 1.022 | 0.976 | 1 1⁄2 | 1.5 | 1.45 | 1.732 | 1.653 | 43⁄64 | 0.7 | 0.591 | 0.09 | 0.03 | 2.25 | 2.5 |

| 1 1⁄8 | 1.125 | 1.149 | 1.098 | 1 11⁄16 | 1.688 | 1.631 | 1.949 | 1.859 | 3⁄4 | 0.78 | 0.658 | 0.09 | 0.03 | 2.5 | 2.75 |

| 1 1⁄4 | 1.25 | 1.277 | 1.223 | 1 7⁄8 | 1.875 | 1.812 | 2.165 | 2.066 | 27⁄32 | 0.876 | 0.749 | 0.09 | 0.03 | 2.75 | 3 |

| 1 3⁄8 | 1.375 | 1.404 | 1.345 | 2 1⁄16 | 2.062 | 1.994 | 2.382 | 2.273 | 29⁄32 | 0.94 | 0.81 | 0.09 | 0.03 | 3 | 3.25 |

| 1 1⁄2 | 1.5 | 1.531 | 1.47 | 2 1⁄4 | 2.25 | 2.175 | 2.598 | 2.48 | 1 | 1.036 | 0.902 | 0.09 | 0.03 | 3.25 | 3.5 |

| 1 5⁄8 | 1.625 | 1.658 | 1.591 | 2 7⁄16 | 2.438 | 2.356 | 2.815 | 2.616 | 1 3⁄32 | 1.116 | 0.978 | 0.09 | 0.03 | 3.5 | 3.75 |

| 1 3⁄4 | 1.75 | 1.785 | 1.716 | 2 5⁄8 | 2.625 | 2.538 | 3.031 | 2.893 | 1 5⁄32 | 1.196 | 1.054 | 0.12 | 0.04 | 3.75 | 4 |

| 1 7⁄8 | 1.875 | 1.912 | 1.839 | 2 13⁄16 | 2.812 | 2.719 | 3.248 | 3.099 | 1 1⁄4 | 1.276 | 1.13 | 0.12 | 0.04 | 4 | 4.25 |

| 2 | 2 | 2.039 | 1.964 | 3 | 3 | 2.9 | 3.464 | 3.306 | 1 11⁄32 | 1.388 | 1.175 | 0.12 | 0.04 | 4.25 | 4.5 |

| 2 1⁄4 | 2.25 | 2.305 | 2.214 | 3 3⁄8 | 3.375 | 3.262 | 3.897 | 3.719 | 1 1⁄2 | 1.548 | 1.327 | 0.19 | 0.06 | 4.75 | 5 |

| 2 1⁄2 | 2.5 | 2.559 | 2.461 | 3 3⁄4 | 3.75 | 3.625 | 4.33 | 4.133 | 1 21⁄32 | 1.708 | 1.479 | 0.19 | 0.06 | 5.25 | 5.5 |

| 2 3⁄4 | 2.75 | 2.827 | 2.711 | 4 1⁄8 | 4.125 | 3.988 | 4.763 | 4.546 | 1 13⁄16 | 1.869 | 1.632 | 0.19 | 0.06 | 5.75 | 6 |

| 3 | 3 | 3.081 | 2.961 | 4 1⁄2 | 4.5 | 4.35 | 5.196 | 4.959 | 2 | 2.06 | 1.815 | 0.19 | 0.06 | 6.25 | 6.5 |

| 3 1⁄4 | 3.25 | 3.335 | 3.21 | 4 7⁄8 | 4.875 | 4.712 | 5.629 | 5.372 | 2 3⁄16 | 2.251 | 1.936 | 0.19 | 0.06 | 6.75 | 7 |

| 3 1⁄2 | 3.5 | 3.589 | 3.461 | 5 1⁄4 | 5.25 | 5.075 | 6.062 | 5.786 | 2 5⁄16 | 2.38 | 2.057 | 0.19 | 0.06 | 7.25 | 7.5 |

| 3 3⁄4 | 3.75 | 3.858 | 3.726 | 5 5⁄8 | 5.625 | 5.437 | 6.495 | 6.198 | 2 1⁄2 | 2.572 | 2.241 | 0.19 | 0.06 | 7.75 | 8 |

| 4 | 4 | 4.111 | 3.975 | 6 | 6 | 5.8 | 6.928 | 6.612 | 2 11⁄16 | 2.764 | 2.424 | 0.19 | 0.06 | 8.25 | 8.5 |

Different Types Of Cupro Nickel 70/30 Bolt

Different Types Of Bolts

- Cupro Nickel 70/30 Bolts

- DIN 2.0882 Carriage Bolts

- ASTM B151 Cupro Nickel 70/30 Hex Bolts

- Cupro Nickel 70/30 Forged Hook Bolts

- ASTM B151 UNS C71500 Eye Bolts

- Cupro Nickel 70/30 Allen Bolts

- Cupro Nickel 70/30 Flange Head Bolts

- 70/30 Cupro Nickel Hex Head Bolts

- 70/30 Cupro Nickel Torx Bolts

- UNS C71500 12-Point U Bolts

- Cupro Nickel 70/30 Countersunk Bolts

- A2-70 Cupro Nickel Bolts

Application of Cupro Nickel 70/30 Bolt

Testing of Cupro Nickel 70/30 Bolt

Packing of Cupro Nickel 70/30 Bolt

Destination Of Cupro Nickel 70/30 Bolt

- City We Deliver

- Country We Export

- People Also Search