Duplex UNS S31803 Stud Bolt

Duplex And Super Duplex Stud Bolt

UNS S31803 Bonding Stud Bolt, Duplex UNS S31803 Tap End Threaded Rod, DIN 1.4462 Full Threaded Stud Bolt, ASTM A479 Duplex S31803 Tap End Stud Bolt, DIN 1.4462 Half Threaded Stud Bolt, Duplex UNS S31803 Flange Stud Bolt.

What is Duplex UNS S31803 Stud Bolt?

Duplex-grade stainless steel is used to make UNS S31803 Duplex Steel Stud Bolts. Superior to austenitic stainless steel are UNS S31803 stud bolts made of duplex steel. Because the alloy can survive stress-related corrosion cracking, the Grade S31803 Fully Threaded Stud Bolt performs well in environments with hostile media.

S31803 Duplex Tap End Stud Bolt is utilized in highly demanding applications, including chemical processing, pressure tanks, and heat exchangers. The material’s main constituents are iron, nitrogen, manganese, silicon, phosphorus, Sulphur, 22% chromium, 3% molybdenum, and 4.5% nickel. The ASTM A479 Duplex S31803 Threaded Rod would provide a fantastic addition to these companies due to the alloy’s superior resistance to components made of chemicals such acids, alkalis, and neutral remedies.

Properties of Duplex S31803 Stud Bolts:

DIN 1.4462 Half Threaded Stud Bolts are further cooling down to 300 Degrees C and should be completed as soon as possible since additional undesirable metallic phases might develop. If standard procedures are followed for welding stainless steels, Duplex Grade S31803 Stud Bolts are equally simple to weld. In these ASME SA479 UNS S31803 Flange Stud Bolts, depending on the geometry of the seam, Industries should avoid the thickness of the steel, and the welding technique, meagre and highly high heat input. Duplex S31803 Stud Bolts are designed to check inter-pass heat and heat input during the welding process.

About Duplex UNS S31803 Stud Bolt

List Of Duplex Steel UNS S31803 Stud Bolt Specifications:

- S31803 Double End Stud Bolts have a round shape, a melting temperature of 2525 to 2630 degrees Celsius, and are available in the A-276 and A-479 alloys.

- Phosphorus, manganese, silica, carbon, Sulphur, chromium, molybdenum, nickel, nitrogen, and iron are all included in the composition of duplex steel stud bolts.

- The minimum yield strength of S31803 Grade PTFE Coated Stud Bolt is 550MPa, while the minimum tensile strength is 800MPa.

- Sulphide stress corrosion and chloride environments have better resistance to various circumstances, making it roughly two times as strong as typical austenitic stainless steels.

- The custom size of Duplex Steel UNS S31803 Stud Bolt varies from 3 millimetres to 200 millimetres.

Duplex Steel UNS S31803 Stud Bolt Application Areas:

Oil Emergence, Petro-Chemical Industries, Chemical Plants, Valves, Sailing Building Contractors, Civil Entrepreneurs, Home Machinery, Submarines, Water Pumping, Engineering Services Industries, energy Production Units (Nuclear, Hydro or Thermopile), Steelworks, Civil Construction Sectors, Railway are just a few of the settings where the Duplex Steel UNS S31803 Stud Bolts product line is used.

Specification Of Duplex UNS S31803 Stud Bolt

| Specifications | ASTM A479, A182 / ASME SA479, SA182 and DIN, ISO ,JIS ,GB, IS, BS, ASTM and all International Standards |

| Size | M3 - M100 | 3/6″ - 4″ | Custom Sizes |

| Length | 3 mm - 200 mm | Custom Sizes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads and UNF, BSW, BSF, METRIC, UNC, or as required |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Head | Hex, Square, Round, Hex flange, Flat, T-head & Triangular etc. |

| Neck type | Hex, Square, Triangular, Oval & Knurled etc. |

| Manufacturing Process | Passivation /plain, Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing. |

| Surface Coating | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Packing | IN BULK: carton, pallet, Small Boxes or customer request |

| Test Certificate | As per EN 10204 / 3.1 Manufacturer Test Certificate, PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Delivery time | Regular product : 7-15 days, Custom product : 2-4 weeks |

Equivalent Grades Duplex UNS S31803 Stud Bolt

| STANDARD | UNS | WNR. |

| Duplex Steel 31803 | S31803 | 1.4462 |

Chemical Composition Duplex UNS S31803 Stud Bolt

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| Duplex Steel S31803 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

Mechanical Properties Duplex UNS S31803 Stud Bolt

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

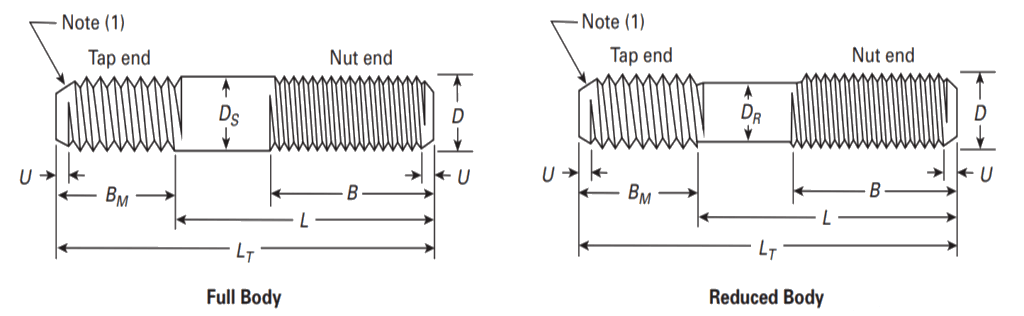

Dimensions Of Duplex UNS S31803 Stud Bolt

Duplex Steel Stud Bolts Dimensions Chart :

| Nominal Size Diameter, D inch | Tap End Full Thread Length, BM | Umax = 2P | Minimum Nut End Full Thread Length, Bmin |

||||||

| Nominal | Min. | Max. | UNC & NC-5 Thread | UNF Thread | 8UN Thread | L ≤ 10 | 10 | L > 16 | |

| 1/4 | 0.375 | 0.350 | 0.400 | 0.100 | 0.071 | ... | 0.750 | 1.000 | 1.500 |

| 5/16 | 0.469 | 0.440 | 0.498 | 0.111 | 0.083 | -- | 0.875 | 1.125 | 1.625 |

| 3/8 | 0.563 | 0.532 | 0.594 | 0.125 | 0.083 | -- | 1.000 | 1.250 | 1.750 |

| 7/16 | 0.656 | 0.620 | 0.692 | 0.143 | 0.100 | -- | 1.125 | 1.375 | 1.875 |

| 1/2 | 0.750 | 0.708 | 0.792 | 0.154 | 0.100 | -- | 1.250 | 1.500 | 2.000 |

| 9/16 | 0.844 | 0.802 | 0.896 | 0.167 | 0.111 | -- | 1.375 | 1.625 | 2.125 |

| 5/8 | 0.938 | 0.892 | 0.983 | 0.182 | 0.111 | -- | 1.500 | 1.750 | 2.250 |

| 3/4 | 1.1.25 | 1.075 | 1.175 | 0.200 | 0.125 | -- | 1.750 | 2.000 | 2.500 |

| 7/8 | 1.313 | 1.258 | 1.368 | 0.222 | 0.143 | -- | 2.000 | 2.250 | 2.750 |

| 1 | 1.500 | 1.438 | 1.562 | 0.250 | 0.167 | -- | 2.250 | 2.500 | 3.000 |

| 1 1/8 | 1.688 | 1.625 | 1.750 | 0.286 | 0.167 | 0.250 | 2.500 | 2.750 | 3.250 |

| 1 1/4 | 1.875 | 1.813 | 1.938 | 0.286 | 0.167 | 0.250 | 2.750 | 3.000 | 3.500 |

| 1 3/8 | 2.063 | 2.000 | 2.125 | 0.333 | 0.167 | 0.250 | 3.000 | 3.250 | 3.750 |

| 1 1/2 | 2.250 | 2.188 | 2.313 | 0.333 | 0.167 | 0.250 | 3.250 | 3.500 | 4.000 |

| 1 5/8 | 2.438 | 2.375 | 2.500 | -- | -- | 0.250 | 3.500 | 3.750 | 4.250 |

| 1 3/4 | 2.625 | 2.563 | 2.688 | 0.400 | -- | 0.250 | 3.750 | 4.000 | 4.500 |

| 1 7/8 | 2.813 | 2.750 | 2.875 | -- | -- | 0.250 | 4.000 | 4.250 | 4.750 |

| 2 | 3.000 | 2.925 | 3.075 | 0.444 | -- | 0.250 | 4.250 | 4.500 | 5.000 |

| 2 1/4 | 3.375 | 3.300 | 3.450 | 0.444 | -- | 0.250 | 4.750 | 5.000 | 5.500 |

| 2 1/2 | 3.750 | 3.675 | 3.825 | 0.500 | -- | 0.250 | 5.250 | 5.500 | 6.000 |

| 2 3/4 | 4.125 | 4.050 | 4.200 | 0.500 | -- | 0.250 | 5.750 | 6.000 | 6.500 |

| 3 | 4.500 | 4.425 | 4.575 | 0.500 | -- | 0.250 | -- | 6.500 | 7.000 |

| 3 1/4 | 4.875 | 4.775 | 4.975 | 0.500 | -- | 0.250 | -- | 7.000 | 7.500 |

| 3 1/2 | 5.250 | 5.150 | 5.350 | 0.500 | -- | 0.250 | -- | 7.500 | 8.000 |

| 3 3/4 | 5.625 | 5.525 | 5.725 | 0.500 | -- | 0.250 | -- | 8.000 | 8.500 |

| 4 | 6.000 | 5.900 | 6.100 | 0.500 | -- | 0.250 | -- | 8.500 | 9.000 |

Different Types Of Duplex UNS S31803 Stud Bolt

Different Types Of Studs Bolts

- Duplex UNS S31803 Full Threaded Rod

- ASTM A479 Duplex S31803 Half Threaded Rod

- UNS S31803 Double End Stud Bolt

- ASTM A479 Duplex S31803 Tap End Stud Bolt

- DIN 1.4462 Full Threaded Stud Bolt

- Duplex UNS S31803 Tap End Threaded Rod

- Duplex UNS S31803 Double End Threaded Rod

- DIN 1.4462 Half Threaded Stud Bolt

- UNS S31803 Bonding Stud Bolt

- Duplex UNS S31803 Flange Stud Bolt

Application of Duplex UNS S31803 Stud Bolt

Testing of Duplex UNS S31803 Stud Bolt

Packing of Duplex UNS S31803 Stud Bolt

Destination Of Duplex UNS S31803 Stud Bolt

- City We Deliver

- Country We Export

- People Also Search