Inconel 601 Bolt

High Nickel Alloys Bolt

ASME SB166 Inconel 601 Hex Bolt, DIN 2.4851 Flange Head Bolt, ASTM B166 Inconel 601 Hex Head Bolt, Alloy 601 Eye Bolt, UNS N06601 U Bolt, Grade Inconel 601 Stud Bolt, Inconel 601 Anchor Bolt, Werkstoff Nr. 2.4851 Allen Bolt

Bolts constructed of Inconel 601 are designed to endure harsh corrosive and high-temperature exposure environments. These bolts have a nickel and chromium alloy that increases their heat, oxidation, and corrosion resistance. Even after prolonged service exposure, the nickel component maintains its ductility and high-temperature strength. This grade of bolts develops a strongly adhering oxide scale that resists spalling under circumstances of high-temperature cycling. Bolts made of Inconel 601 are frequently utilised in conditions demanding high mechanical stress and surface stability. The fasteners are exceptionally carburization resistant and have outstanding creep rupture strength. These exhibit strong resistance to water corrosion as well. These have superior mechanical properties and are simple to fabricate and machine. The fasteners are both hot- and cold-worked, and they may be put together with ease utilising welding processes.

One of its main advantages is that Inconel 601 Bolts display corrosion resistance in aquatic conditions. Corrosion generally moves more quickly in watery media. A Nickel Alloy 601 Bolt corrodes much more slowly than other metals because to the strong chemical basis of nickel and chromium in the alloy. The microstructure of this alloy allows it to be used at cryogenic temperatures.

About Inconel 601 Bolt

Specification Of Inconel 601 Bolt

| Specifications | ASTM B564, ASME SB564 and DIN, ISO ,JIS ,GB, IS, BS, ASTM and all International Standards |

| Size | M3 - M100 | 3/6″ - 4″ | Custom Sizes |

| Length | 3 mm - 200 mm | Custom Sizes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads and UNF, BSW, BSF, METRIC, UNC, or as required |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Head | Hex, Square, Round, Hex flange, Flat, T-head & Triangular etc. |

| Neck type | Hex, Square, Triangular, Oval & Knurled etc. |

| Manufacturing Process | Passivation /plain, Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing. |

| Surface Coating | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Packing | IN BULK: carton, pallet, Small Boxes or customer request |

| Test Certificate | As per EN 10204 / 3.1 Manufacturer Test Certificate, PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Delivery time | Regular product : 7-15 days, Custom product : 2-4 weeks |

Equivalent Grades Inconel 601 Bolt

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Alloy 601 | N06601 | 2.4851 | NiCr23Fe | NiCr15Fe | NCF 601 | NA 49 | XH60BT | ЭИ868 |

Chemical Composition Inconel 601 Bolt

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 601 | 0.10 max | 1.0 max | 0.5 max | 0.015 max | 1.0 max | Balance | 58.0 – 63.0 | 21.0 – 25.0 |

Mechanical Properties Inconel 601 Bolt

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

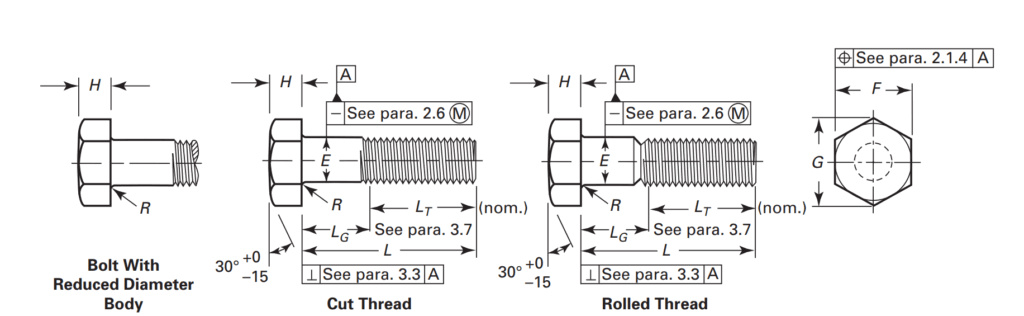

Dimensions Of Inconel 601 Bolt

High Nickel Alloys Bolts Dimensions Chart :

| Nominal Size or Basic Product Diameter | Full-Size Body Diameter, E | Width Across Flats, F | Width Across Corners, G | Head Height, H Basic | Radius of Fillet, R | Nominal Thread Length for Bolt Lengths, LT |

|||||||||

| inch | mm | Max | Min | Basic inch | Max | Min | Max | Min | Basic inch | Max | Min | Max | Min | 6 in. and Shoter | Over 6 in. |

| 1⁄4 | 0.25 | 0.26 | 0.237 | 7⁄16 | 0.438 | 0.425 | 0.505 | 0.484 | 11⁄64 | 0.188 | 0.15 | 0.03 | 0.01 | 0.75 | 1 |

| 5⁄16 | 0.3125 | 0.324 | 0.298 | 1⁄2 | 0.5 | 0.484 | 0.577 | 0.552 | 7⁄32 | 0.235 | 0.195 | 0.03 | 0.01 | 0.875 | 1.125 |

| 3⁄8 | 0.375 | 0.388 | 0.36 | 9⁄16 | 0.562 | 0.544 | 0.65 | 0.62 | 1⁄4 | 0.268 | 0.226 | 0.03 | 0.01 | 1 | 1.25 |

| 7⁄16 | 0.4375 | 0.452 | 0.421 | 5⁄8 | 0.625 | 0.603 | 0.722 | 0.687 | 19⁄64 | 0.316 | 0.272 | 0.03 | 0.01 | 1.125 | 1.375 |

| 1⁄2 | 0.5 | 0.515 | 0.482 | 3⁄4 | 0.75 | 0.725 | 0.866 | 0.826 | 11⁄32 | 0.364 | 0.302 | 0.03 | 0.01 | 1.25 | 1.5 |

| 5⁄8 | 0.625 | 0.642 | 0.605 | 15⁄16 | 0.938 | 0.906 | 1.083 | 1.033 | 27⁄64 | 0.444 | 0.378 | 0.06 | 0.02 | 1.5 | 1.75 |

| 3⁄4 | 0.75 | 0.768 | 0.729 | 11⁄8 | 1.125 | 1.088 | 1.299 | 1.24 | 1⁄2 | 0.524 | 0.455 | 0.06 | 0.02 | 1.75 | 2 |

| 7⁄8 | 0.875 | 0.895 | 0.852 | 1 5⁄16 | 1.312 | 1.269 | 1.516 | 1.447 | 37⁄64 | 0.604 | 0.531 | 0.06 | 0.02 | 2 | 2.25 |

| 1 | 1 | 1.022 | 0.976 | 1 1⁄2 | 1.5 | 1.45 | 1.732 | 1.653 | 43⁄64 | 0.7 | 0.591 | 0.09 | 0.03 | 2.25 | 2.5 |

| 1 1⁄8 | 1.125 | 1.149 | 1.098 | 1 11⁄16 | 1.688 | 1.631 | 1.949 | 1.859 | 3⁄4 | 0.78 | 0.658 | 0.09 | 0.03 | 2.5 | 2.75 |

| 1 1⁄4 | 1.25 | 1.277 | 1.223 | 1 7⁄8 | 1.875 | 1.812 | 2.165 | 2.066 | 27⁄32 | 0.876 | 0.749 | 0.09 | 0.03 | 2.75 | 3 |

| 1 3⁄8 | 1.375 | 1.404 | 1.345 | 2 1⁄16 | 2.062 | 1.994 | 2.382 | 2.273 | 29⁄32 | 0.94 | 0.81 | 0.09 | 0.03 | 3 | 3.25 |

| 1 1⁄2 | 1.5 | 1.531 | 1.47 | 2 1⁄4 | 2.25 | 2.175 | 2.598 | 2.48 | 1 | 1.036 | 0.902 | 0.09 | 0.03 | 3.25 | 3.5 |

| 1 5⁄8 | 1.625 | 1.658 | 1.591 | 2 7⁄16 | 2.438 | 2.356 | 2.815 | 2.616 | 1 3⁄32 | 1.116 | 0.978 | 0.09 | 0.03 | 3.5 | 3.75 |

| 1 3⁄4 | 1.75 | 1.785 | 1.716 | 2 5⁄8 | 2.625 | 2.538 | 3.031 | 2.893 | 1 5⁄32 | 1.196 | 1.054 | 0.12 | 0.04 | 3.75 | 4 |

| 1 7⁄8 | 1.875 | 1.912 | 1.839 | 2 13⁄16 | 2.812 | 2.719 | 3.248 | 3.099 | 1 1⁄4 | 1.276 | 1.13 | 0.12 | 0.04 | 4 | 4.25 |

| 2 | 2 | 2.039 | 1.964 | 3 | 3 | 2.9 | 3.464 | 3.306 | 1 11⁄32 | 1.388 | 1.175 | 0.12 | 0.04 | 4.25 | 4.5 |

| 2 1⁄4 | 2.25 | 2.305 | 2.214 | 3 3⁄8 | 3.375 | 3.262 | 3.897 | 3.719 | 1 1⁄2 | 1.548 | 1.327 | 0.19 | 0.06 | 4.75 | 5 |

| 2 1⁄2 | 2.5 | 2.559 | 2.461 | 3 3⁄4 | 3.75 | 3.625 | 4.33 | 4.133 | 1 21⁄32 | 1.708 | 1.479 | 0.19 | 0.06 | 5.25 | 5.5 |

| 2 3⁄4 | 2.75 | 2.827 | 2.711 | 4 1⁄8 | 4.125 | 3.988 | 4.763 | 4.546 | 1 13⁄16 | 1.869 | 1.632 | 0.19 | 0.06 | 5.75 | 6 |

| 3 | 3 | 3.081 | 2.961 | 4 1⁄2 | 4.5 | 4.35 | 5.196 | 4.959 | 2 | 2.06 | 1.815 | 0.19 | 0.06 | 6.25 | 6.5 |

| 3 1⁄4 | 3.25 | 3.335 | 3.21 | 4 7⁄8 | 4.875 | 4.712 | 5.629 | 5.372 | 2 3⁄16 | 2.251 | 1.936 | 0.19 | 0.06 | 6.75 | 7 |

| 3 1⁄2 | 3.5 | 3.589 | 3.461 | 5 1⁄4 | 5.25 | 5.075 | 6.062 | 5.786 | 2 5⁄16 | 2.38 | 2.057 | 0.19 | 0.06 | 7.25 | 7.5 |

| 3 3⁄4 | 3.75 | 3.858 | 3.726 | 5 5⁄8 | 5.625 | 5.437 | 6.495 | 6.198 | 2 1⁄2 | 2.572 | 2.241 | 0.19 | 0.06 | 7.75 | 8 |

| 4 | 4 | 4.111 | 3.975 | 6 | 6 | 5.8 | 6.928 | 6.612 | 2 11⁄16 | 2.764 | 2.424 | 0.19 | 0.06 | 8.25 | 8.5 |

Different Types Of Inconel 601 Bolt

Different Types Of Bolts

- Inconel 601 Bolts

- DIN 2.4851 Carriage Bolts

- ASTM B166 Inconel 601 Hex Bolts

- Inconel 601 Forged Hook Bolts

- ASTM B166 Alloy 601 Eye Bolts

- Inconel 601 Allen Bolts

- Inconel 601 Flange Head Bolts

- 601 Inconel Hex Head Bolts

- 601 Inconel Torx Bolts

- UNS N06601 12-Point U Bolts

- Inconel 601 Countersunk Bolts

- A2-70 Inconel Bolts

Application of Inconel 601 Bolt

Testing of Inconel 601 Bolt

Packing of Inconel 601 Bolt

Destination Of Inconel 601 Bolt

- City We Deliver

- Country We Export

- People Also Search