Inconel 625 Bolt

Home » Inconel 625 Bolt

High Nickel Alloys Bolt

ASTM B446 Inconel 625 Anchor Bolt, UNS N06625 Hex Bolt, ASME SB446 Inconel 625 Stud Bolt, Werkstoff Nr. 2.4856 Flange Head Bolt, Inconel 625 Hex Head Bolt, DIN 2.4856 Eye Bolt, Inconel 625 Allen Bolt, Alloy 625 U Bolt

Inconel Alloy 625 Bolts, which outperform many other high-temperature alloys under periodic warming and cooling circumstances, are available at Shree Ashapura Steel Centre in a large selection. When housing engine controls, fuel, and hydraulic line tubing in resistance-welded honeycomb constructions, Inconel 625 bolts are frequently employed. Inconel 625 bolts have good resistance to corrosion in crevices and saltwater pitting. They have a disk-shaped morphology and are coherent with the matrix. In acidic, fresh water, salt water, neutral salts, and the air, Inconel 625 Bolts seldom ever have an assault. Chemical process equipment handling mixed acids that are both oxidizing and reducing are some typical applications for Inconel 625 square nuts. Inconel 625 U-Bolts are very resistant to pitting and crevice corrosion and can withstand various extremely hostile situations. Lock bolts made of Inconel 625 may be machined and welded easily in a shop. Almost minor stress corrosion cracking caused by chloride occurs in Inconel 625 eye bolts. Other applications for Inconel 625 Eye Nuts include reaction vessels, furnace hardware, heat exchangers, ductwork for gas turbine engines, tubes for the generation of sour gas, and acid-producing machinery. These Inconel 625 T-Bolts are made of an alloy of nickel, chromium, and molybdenum with the addition of niobium, which works in conjunction with the molybdenum to stiffen the matrix of the alloy and offers great strength without the need for strengthening heat treatment.

Previous

Next

About Inconel 625 Bolt

This is due to the impressive performance of this nickel-containing Inconel 625 bolt, especially in the manufacture of phosphoric acid, the third-largest formic acid product. The Inconel 625 bolts come into touch with certain contaminants, such as sulphates, fluoride ions, and fluosilicates, at the time of wet processing of phosphoric acid. The Alloy 625 bolts facilitates the efficient processing of phosphoric acid since it is resistant to these substances.

Specification Of Inconel 625 Bolt

| Specifications | ASTM B564, ASME SB564 and DIN, ISO ,JIS ,GB, IS, BS, ASTM and all International Standards |

| Size | M3 - M100 | 3/6″ - 4″ | Custom Sizes |

| Length | 3 mm - 200 mm | Custom Sizes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads and UNF, BSW, BSF, METRIC, UNC, or as required |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Head | Hex, Square, Round, Hex flange, Flat, T-head & Triangular etc. |

| Neck type | Hex, Square, Triangular, Oval & Knurled etc. |

| Manufacturing Process | Passivation /plain, Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing. |

| Surface Coating | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Packing | IN BULK: carton, pallet, Small Boxes or customer request |

| Test Certificate | As per EN 10204 / 3.1 Manufacturer Test Certificate, PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Delivery time | Regular product : 7-15 days, Custom product : 2-4 weeks |

Equivalent Grades Inconel 625 Bolt

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST | OR |

| Inconel 625 | N06625 | 2.4856 | NC22DNB4M | NiCr22Mo9Nb | NCF 625 | NA 21 | ХН75МБТЮ | ЭИ602 |

Chemical Composition Inconel 625 Bolt

| Grade | C | Mn | Si | S | Al | Fe | Ti | Cr2 | Mo | Nb + Ta | Ni |

| 625 | 0.10 | 0.50 | 0.50 | 0.015 | 0.40 | 5.0 | 0.40 | 20.0-23.0 | 8.0-10.0 | 3.15–4.15 | 58.0 min |

Mechanical Properties Inconel 625 Bolt

| Grade | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 625 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi - 75,000 , MPa - 517 | Psi - 1,35,000 , MPa -930 | 42.5 % |

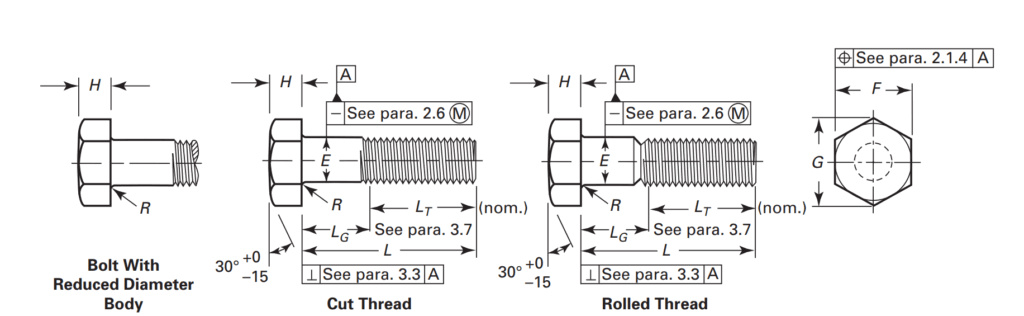

Dimensions Of Inconel 625 Bolt

High Nickel Alloys Bolts Dimensions Chart :

| Nominal Size or Basic Product Diameter | Full-Size Body Diameter, E | Width Across Flats, F | Width Across Corners, G | Head Height, H Basic | Radius of Fillet, R | Nominal Thread Length for Bolt Lengths, LT |

|||||||||

| inch | mm | Max | Min | Basic inch | Max | Min | Max | Min | Basic inch | Max | Min | Max | Min | 6 in. and Shoter | Over 6 in. |

| 1⁄4 | 0.25 | 0.26 | 0.237 | 7⁄16 | 0.438 | 0.425 | 0.505 | 0.484 | 11⁄64 | 0.188 | 0.15 | 0.03 | 0.01 | 0.75 | 1 |

| 5⁄16 | 0.3125 | 0.324 | 0.298 | 1⁄2 | 0.5 | 0.484 | 0.577 | 0.552 | 7⁄32 | 0.235 | 0.195 | 0.03 | 0.01 | 0.875 | 1.125 |

| 3⁄8 | 0.375 | 0.388 | 0.36 | 9⁄16 | 0.562 | 0.544 | 0.65 | 0.62 | 1⁄4 | 0.268 | 0.226 | 0.03 | 0.01 | 1 | 1.25 |

| 7⁄16 | 0.4375 | 0.452 | 0.421 | 5⁄8 | 0.625 | 0.603 | 0.722 | 0.687 | 19⁄64 | 0.316 | 0.272 | 0.03 | 0.01 | 1.125 | 1.375 |

| 1⁄2 | 0.5 | 0.515 | 0.482 | 3⁄4 | 0.75 | 0.725 | 0.866 | 0.826 | 11⁄32 | 0.364 | 0.302 | 0.03 | 0.01 | 1.25 | 1.5 |

| 5⁄8 | 0.625 | 0.642 | 0.605 | 15⁄16 | 0.938 | 0.906 | 1.083 | 1.033 | 27⁄64 | 0.444 | 0.378 | 0.06 | 0.02 | 1.5 | 1.75 |

| 3⁄4 | 0.75 | 0.768 | 0.729 | 11⁄8 | 1.125 | 1.088 | 1.299 | 1.24 | 1⁄2 | 0.524 | 0.455 | 0.06 | 0.02 | 1.75 | 2 |

| 7⁄8 | 0.875 | 0.895 | 0.852 | 1 5⁄16 | 1.312 | 1.269 | 1.516 | 1.447 | 37⁄64 | 0.604 | 0.531 | 0.06 | 0.02 | 2 | 2.25 |

| 1 | 1 | 1.022 | 0.976 | 1 1⁄2 | 1.5 | 1.45 | 1.732 | 1.653 | 43⁄64 | 0.7 | 0.591 | 0.09 | 0.03 | 2.25 | 2.5 |

| 1 1⁄8 | 1.125 | 1.149 | 1.098 | 1 11⁄16 | 1.688 | 1.631 | 1.949 | 1.859 | 3⁄4 | 0.78 | 0.658 | 0.09 | 0.03 | 2.5 | 2.75 |

| 1 1⁄4 | 1.25 | 1.277 | 1.223 | 1 7⁄8 | 1.875 | 1.812 | 2.165 | 2.066 | 27⁄32 | 0.876 | 0.749 | 0.09 | 0.03 | 2.75 | 3 |

| 1 3⁄8 | 1.375 | 1.404 | 1.345 | 2 1⁄16 | 2.062 | 1.994 | 2.382 | 2.273 | 29⁄32 | 0.94 | 0.81 | 0.09 | 0.03 | 3 | 3.25 |

| 1 1⁄2 | 1.5 | 1.531 | 1.47 | 2 1⁄4 | 2.25 | 2.175 | 2.598 | 2.48 | 1 | 1.036 | 0.902 | 0.09 | 0.03 | 3.25 | 3.5 |

| 1 5⁄8 | 1.625 | 1.658 | 1.591 | 2 7⁄16 | 2.438 | 2.356 | 2.815 | 2.616 | 1 3⁄32 | 1.116 | 0.978 | 0.09 | 0.03 | 3.5 | 3.75 |

| 1 3⁄4 | 1.75 | 1.785 | 1.716 | 2 5⁄8 | 2.625 | 2.538 | 3.031 | 2.893 | 1 5⁄32 | 1.196 | 1.054 | 0.12 | 0.04 | 3.75 | 4 |

| 1 7⁄8 | 1.875 | 1.912 | 1.839 | 2 13⁄16 | 2.812 | 2.719 | 3.248 | 3.099 | 1 1⁄4 | 1.276 | 1.13 | 0.12 | 0.04 | 4 | 4.25 |

| 2 | 2 | 2.039 | 1.964 | 3 | 3 | 2.9 | 3.464 | 3.306 | 1 11⁄32 | 1.388 | 1.175 | 0.12 | 0.04 | 4.25 | 4.5 |

| 2 1⁄4 | 2.25 | 2.305 | 2.214 | 3 3⁄8 | 3.375 | 3.262 | 3.897 | 3.719 | 1 1⁄2 | 1.548 | 1.327 | 0.19 | 0.06 | 4.75 | 5 |

| 2 1⁄2 | 2.5 | 2.559 | 2.461 | 3 3⁄4 | 3.75 | 3.625 | 4.33 | 4.133 | 1 21⁄32 | 1.708 | 1.479 | 0.19 | 0.06 | 5.25 | 5.5 |

| 2 3⁄4 | 2.75 | 2.827 | 2.711 | 4 1⁄8 | 4.125 | 3.988 | 4.763 | 4.546 | 1 13⁄16 | 1.869 | 1.632 | 0.19 | 0.06 | 5.75 | 6 |

| 3 | 3 | 3.081 | 2.961 | 4 1⁄2 | 4.5 | 4.35 | 5.196 | 4.959 | 2 | 2.06 | 1.815 | 0.19 | 0.06 | 6.25 | 6.5 |

| 3 1⁄4 | 3.25 | 3.335 | 3.21 | 4 7⁄8 | 4.875 | 4.712 | 5.629 | 5.372 | 2 3⁄16 | 2.251 | 1.936 | 0.19 | 0.06 | 6.75 | 7 |

| 3 1⁄2 | 3.5 | 3.589 | 3.461 | 5 1⁄4 | 5.25 | 5.075 | 6.062 | 5.786 | 2 5⁄16 | 2.38 | 2.057 | 0.19 | 0.06 | 7.25 | 7.5 |

| 3 3⁄4 | 3.75 | 3.858 | 3.726 | 5 5⁄8 | 5.625 | 5.437 | 6.495 | 6.198 | 2 1⁄2 | 2.572 | 2.241 | 0.19 | 0.06 | 7.75 | 8 |

| 4 | 4 | 4.111 | 3.975 | 6 | 6 | 5.8 | 6.928 | 6.612 | 2 11⁄16 | 2.764 | 2.424 | 0.19 | 0.06 | 8.25 | 8.5 |

Different Types Of Inconel 625 Bolt

Different Types Of Bolts

- Inconel 625 Allen Bolts

- 625 Inconel Hex Head Bolts

- ASTM B166 Inconel 625 Hex Bolts

- Inconel Alloy 625 Flange Head Bolts

- Inconel 625 Bolts

- UNS N06625 12-Point U Bolts

- Inconel 625 Countersunk Bolts

- ASTM B166 Inconel 625 Eye Bolts

- Inconel 625 Forged Hook Bolts

- A2-70 Inconel Bolts

- DIN 2.4856 Carriage Bolts

- 625 Inconel Torx Bolts

Application of Inconel 625 Bolt

Construction

Bridges

Engineering

General Structural Purposes

Petrochemical Industry

Ship Building

Previous

Next

Testing of Inconel 625 Bolt

Chemical Analysis

Deimension

Fasteners-testings

Flaring Test

Hardness Test

nondestructive-testing

Previous

Next

Packing of Inconel 625 Bolt

Wrapping Machine Steel pipe

Wooden Boxes

seamless pipe Packing

Packing Systems

Machine Fasteners Packaging

Fasteners Packaging

Previous

Next

Destination Of Inconel 625 Bolt

- City We Deliver

- Country We Export

- People Also Search

Alloy 625 U Bolt Stockist in Pune, Inconel 625 Hex Head Bolt Manufacturer in Ahmedabad, DIN 2.4856 Hex Bolt Exporter in Pimpri-Chinchwad, UNS N06625 Stud Bolt Stockist in Coimbatore, ASME SB446 Inconel 625 Anchor Bolt Exporter in Bangaloren, ASTM B446 Inconel 625 Eye Bolt Supplier in Hyderabad, Werkstoff Nr. 2.4856 Flange Head Bolt Supplier in Chennai

Inconel 625 U Bolt Stockist in Indonesia, DIN 2.4856 Hex Head Bolt Exporter in Tanzania, Inconel 625 Hex Bolt Manufacturer in Nigeria, Alloy 625 Allen Bolt Stockist in Dubai, UNS N06625 U Bolt Stockist in South Africa, Inconel 625 Anchor Bolt Manufacturer in UAE, ASME SB446 Inconel 625 Stud Bolt Exporter in Saudi Arabia, Werkstoff Nr. 2.4856 Allen Bolt Manufacturer in Singapore

ASTM B446 Inconel 625 U Bolt Grade Chart, Werkstoff Nr. 2.4856 Eye Bolt Weight Calculator, Inconel 625 Allen Bolt Price Per Kg, DIN 2.4856 Anchor Bolt at Factory Price, ASME SB446 Inconel 625 Hex Bolt Price List in India, Werkstoff Nr. 2.4856 Stud Bolt Specification, Alloy 625 Stud Bolt Weight Chart, Inconel 625 Flange Head Bolt Price List, Inconel 625 Eye Bolt at Factory Price