Inconel 718 Bolt

Home » Inconel 718 Bolt

High Nickel Alloys Bolt

718 Inconel Hex Head Bolt, Alloy 718 U Bolt, UNS N07718 Allen Bolt, Werkstoff Nr. 2.4668 Flange Head Bolt, ASME SB637 Inconel 718 Eye Bolt, DIN 2.4668 Hex Bolt, Inconel 718 Stud Bolt, ASTM B637 Inconel 718 Anchor Bolt

Bolts made of the solid Inconel 718 are widely utilised in a variety of industrial sectors, and Shree Ashapura Steel Centre is a prominent manufacturer, supplier, and stockiest of these products. According to the requirements of our international clientele, these bolts are offered in a wide variety of kinds, diameters, lengths, and standards. Among the most popular and versatile grades of hardenable Inconel alloys, Inconel 718 has chromium-nickel composition together with a negligible quantity of titanium and aluminium. This unique chemical makeup provides superior resistant to oxidization and corrosion. The nickel content provides superior tensile strength, stressed rupture, and creep-rupture qualities at high temperatures. We use this alloy to create top-grade Inconel 718 Fasteners that can easily withstand situations of higher temperature and pressure because of its exceptional qualities. These fasteners provide superior resistance to pitting and crevice cracking. The fasteners we offer have exceptional resistance to chloride ion stress corrosion cracking, general corrosion, and aqueous corrosion. Even at cryogenic temperatures, our Inconel 718 Fasteners can operate correctly and effectively.

Previous

Next

About Inconel 718 Bolt

Corrosion and oxidation resistance are characteristics of Inconel alloys. High levels of nickel, chromium, and molybdenum make up Inconel 718. These alloys have exceptional resistance to corrosion in crevices and acid-induced pitting. Under any pressures or temperatures, they don’t easily deform or dissociate. The alloys of this grade are robust, and the Inconel 718 used to make them have improved mechanical characteristics. They have excellent rupture resistance, good tensile strength, and yield strength. They are widely utilised in the chemical, aerospace, pollution control, nuclear, gas turbine, valve, and fastener sectors, among others. The best providers of Inconel 718 are us. We work hard to provide top-notch goods at affordable prices.

Specification Of Inconel 718 Bolt

| Specifications | ASTM B564, ASME SB564 and DIN, ISO ,JIS ,GB, IS, BS, ASTM and all International Standards |

| Size | M3 - M100 | 3/6″ - 4″ | Custom Sizes |

| Length | 3 mm - 200 mm | Custom Sizes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads and UNF, BSW, BSF, METRIC, UNC, or as required |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Head | Hex, Square, Round, Hex flange, Flat, T-head & Triangular etc. |

| Neck type | Hex, Square, Triangular, Oval & Knurled etc. |

| Manufacturing Process | Passivation /plain, Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing. |

| Surface Coating | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Packing | IN BULK: carton, pallet, Small Boxes or customer request |

| Test Certificate | As per EN 10204 / 3.1 Manufacturer Test Certificate, PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Delivery time | Regular product : 7-15 days, Custom product : 2-4 weeks |

Equivalent Grades Inconel 718 Bolt

| STANDARD | WERKSTOFF NR. | UNS |

| Inconel 718 | 2.4668 | N07718 |

Chemical Composition Inconel 718 Bolt

| Grade | C | Mn | Si | P | S | Ni | Cr | B | Mo | Co | Al | Ti | Nb | Cu |

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.015 max | 0.015 max | 50 – 55 | 17 – 21 | 0.006 max | 2.8 – 3.3 | 1.0 max | 0.2 – 0.8 | 0.65 – 1.15 | 4.75 – 5.5 | 0.3 max |

Mechanical Properties Inconel 718 Bolt

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 718 | 8.2 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000, MPa – 930 | Psi – 75,000, MPa – 482 | 45 % |

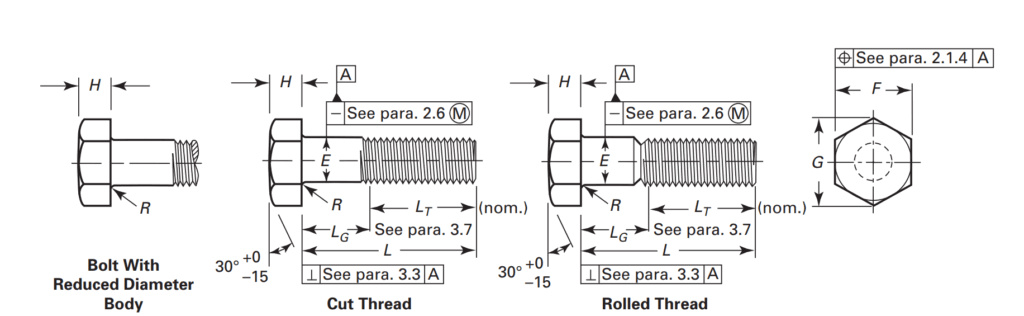

Dimensions Of Inconel 718 Bolt

High Nickel Alloys Bolts Dimensions Chart :

| Nominal Size or Basic Product Diameter | Full-Size Body Diameter, E | Width Across Flats, F | Width Across Corners, G | Head Height, H Basic | Radius of Fillet, R | Nominal Thread Length for Bolt Lengths, LT |

|||||||||

| inch | mm | Max | Min | Basic inch | Max | Min | Max | Min | Basic inch | Max | Min | Max | Min | 6 in. and Shoter | Over 6 in. |

| 1⁄4 | 0.25 | 0.26 | 0.237 | 7⁄16 | 0.438 | 0.425 | 0.505 | 0.484 | 11⁄64 | 0.188 | 0.15 | 0.03 | 0.01 | 0.75 | 1 |

| 5⁄16 | 0.3125 | 0.324 | 0.298 | 1⁄2 | 0.5 | 0.484 | 0.577 | 0.552 | 7⁄32 | 0.235 | 0.195 | 0.03 | 0.01 | 0.875 | 1.125 |

| 3⁄8 | 0.375 | 0.388 | 0.36 | 9⁄16 | 0.562 | 0.544 | 0.65 | 0.62 | 1⁄4 | 0.268 | 0.226 | 0.03 | 0.01 | 1 | 1.25 |

| 7⁄16 | 0.4375 | 0.452 | 0.421 | 5⁄8 | 0.625 | 0.603 | 0.722 | 0.687 | 19⁄64 | 0.316 | 0.272 | 0.03 | 0.01 | 1.125 | 1.375 |

| 1⁄2 | 0.5 | 0.515 | 0.482 | 3⁄4 | 0.75 | 0.725 | 0.866 | 0.826 | 11⁄32 | 0.364 | 0.302 | 0.03 | 0.01 | 1.25 | 1.5 |

| 5⁄8 | 0.625 | 0.642 | 0.605 | 15⁄16 | 0.938 | 0.906 | 1.083 | 1.033 | 27⁄64 | 0.444 | 0.378 | 0.06 | 0.02 | 1.5 | 1.75 |

| 3⁄4 | 0.75 | 0.768 | 0.729 | 11⁄8 | 1.125 | 1.088 | 1.299 | 1.24 | 1⁄2 | 0.524 | 0.455 | 0.06 | 0.02 | 1.75 | 2 |

| 7⁄8 | 0.875 | 0.895 | 0.852 | 1 5⁄16 | 1.312 | 1.269 | 1.516 | 1.447 | 37⁄64 | 0.604 | 0.531 | 0.06 | 0.02 | 2 | 2.25 |

| 1 | 1 | 1.022 | 0.976 | 1 1⁄2 | 1.5 | 1.45 | 1.732 | 1.653 | 43⁄64 | 0.7 | 0.591 | 0.09 | 0.03 | 2.25 | 2.5 |

| 1 1⁄8 | 1.125 | 1.149 | 1.098 | 1 11⁄16 | 1.688 | 1.631 | 1.949 | 1.859 | 3⁄4 | 0.78 | 0.658 | 0.09 | 0.03 | 2.5 | 2.75 |

| 1 1⁄4 | 1.25 | 1.277 | 1.223 | 1 7⁄8 | 1.875 | 1.812 | 2.165 | 2.066 | 27⁄32 | 0.876 | 0.749 | 0.09 | 0.03 | 2.75 | 3 |

| 1 3⁄8 | 1.375 | 1.404 | 1.345 | 2 1⁄16 | 2.062 | 1.994 | 2.382 | 2.273 | 29⁄32 | 0.94 | 0.81 | 0.09 | 0.03 | 3 | 3.25 |

| 1 1⁄2 | 1.5 | 1.531 | 1.47 | 2 1⁄4 | 2.25 | 2.175 | 2.598 | 2.48 | 1 | 1.036 | 0.902 | 0.09 | 0.03 | 3.25 | 3.5 |

| 1 5⁄8 | 1.625 | 1.658 | 1.591 | 2 7⁄16 | 2.438 | 2.356 | 2.815 | 2.616 | 1 3⁄32 | 1.116 | 0.978 | 0.09 | 0.03 | 3.5 | 3.75 |

| 1 3⁄4 | 1.75 | 1.785 | 1.716 | 2 5⁄8 | 2.625 | 2.538 | 3.031 | 2.893 | 1 5⁄32 | 1.196 | 1.054 | 0.12 | 0.04 | 3.75 | 4 |

| 1 7⁄8 | 1.875 | 1.912 | 1.839 | 2 13⁄16 | 2.812 | 2.719 | 3.248 | 3.099 | 1 1⁄4 | 1.276 | 1.13 | 0.12 | 0.04 | 4 | 4.25 |

| 2 | 2 | 2.039 | 1.964 | 3 | 3 | 2.9 | 3.464 | 3.306 | 1 11⁄32 | 1.388 | 1.175 | 0.12 | 0.04 | 4.25 | 4.5 |

| 2 1⁄4 | 2.25 | 2.305 | 2.214 | 3 3⁄8 | 3.375 | 3.262 | 3.897 | 3.719 | 1 1⁄2 | 1.548 | 1.327 | 0.19 | 0.06 | 4.75 | 5 |

| 2 1⁄2 | 2.5 | 2.559 | 2.461 | 3 3⁄4 | 3.75 | 3.625 | 4.33 | 4.133 | 1 21⁄32 | 1.708 | 1.479 | 0.19 | 0.06 | 5.25 | 5.5 |

| 2 3⁄4 | 2.75 | 2.827 | 2.711 | 4 1⁄8 | 4.125 | 3.988 | 4.763 | 4.546 | 1 13⁄16 | 1.869 | 1.632 | 0.19 | 0.06 | 5.75 | 6 |

| 3 | 3 | 3.081 | 2.961 | 4 1⁄2 | 4.5 | 4.35 | 5.196 | 4.959 | 2 | 2.06 | 1.815 | 0.19 | 0.06 | 6.25 | 6.5 |

| 3 1⁄4 | 3.25 | 3.335 | 3.21 | 4 7⁄8 | 4.875 | 4.712 | 5.629 | 5.372 | 2 3⁄16 | 2.251 | 1.936 | 0.19 | 0.06 | 6.75 | 7 |

| 3 1⁄2 | 3.5 | 3.589 | 3.461 | 5 1⁄4 | 5.25 | 5.075 | 6.062 | 5.786 | 2 5⁄16 | 2.38 | 2.057 | 0.19 | 0.06 | 7.25 | 7.5 |

| 3 3⁄4 | 3.75 | 3.858 | 3.726 | 5 5⁄8 | 5.625 | 5.437 | 6.495 | 6.198 | 2 1⁄2 | 2.572 | 2.241 | 0.19 | 0.06 | 7.75 | 8 |

| 4 | 4 | 4.111 | 3.975 | 6 | 6 | 5.8 | 6.928 | 6.612 | 2 11⁄16 | 2.764 | 2.424 | 0.19 | 0.06 | 8.25 | 8.5 |

Different Types Of Inconel 718 Bolt

Different Types Of Bolts

- Inconel 718 Bolts

- DIN 2.4668 Carriage Bolts

- ASTM B637 Inconel 718 Hex Bolts

- Inconel 718 Forged Hook Bolts

- ASTM B637 Inconel 718 Stud Bolts

- Inconel 718 Allen Bolts

- Inconel Alloy 718 Flange Head Bolts

- 718 Inconel Hex Head Bolts

- 718 Inconel Torx Bolts

- UNS N07718 12-Point U Bolts

- Inconel 718 Countersunk Bolts

- A2-70 Inconel Bolts

Application of Inconel 718 Bolt

Construction

Bridges

Engineering

General Structural Purposes

Petrochemical Industry

Ship Building

Previous

Next

Testing of Inconel 718 Bolt

Chemical Analysis

Deimension

Fasteners-testings

Flaring Test

Hardness Test

nondestructive-testing

Previous

Next

Packing of Inconel 718 Bolt

Wrapping Machine Steel pipe

Wooden Boxes

seamless pipe Packing

Packing Systems

Machine Fasteners Packaging

Fasteners Packaging

Previous

Next

Destination Of Inconel 718 Bolt

- City We Deliver

- Country We Export

- People Also Search

ASME SB637 Inconel 718 Hex Bolt Exporter in Pimpri-Chinchwad, UNS N07718 Allen Bolt Manufacturer in Jamnagar, Alloy 718 U Bolt Stockist in Pune, 718 Inconel Hex Head Bolt Manufacturer in Ahmedabad, Inconel 718 Anchor Bolt Exporter in Bangalore, ASTM B637 Inconel 718 Eye Bolt Supplier in Hyderabad, Werkstoff Nr. 2.4668 Flange Head Bolt Supplier in Chennai

Inconel 718 Stud Bolt Exporter in Saudi Arabia, Werkstoff Nr. 2.4668 Flange Head Bolt Supplier in Qatar, ASTM B637 Inconel 718 Eye Bolt Supplier in Malaysia, WNRF 2.4668 Allen Bolt Manufacturer in Singapore, ASME SB637 Inconel 718 Hex Head Bolt Exporter in Tanzania, DIN 2.4668 U Bolt Stockist in South Africa, ASTM B637 Inconel 718 Allen Bolt Exporter in Argentina

Alloy 718 Stud Bolt Weight Chart, Inconel 718 Hex Bolt Price List in India, ASME SB637 Inconel 718 Anchor Bolt at Factory Price, WNRF 2.4668 Stud Bolt Specification, DIN 2.4668 Hex Head Bolt Catalogue, Inconel 718 Eye Bolt at Factory Price, 718 Inconel Flange Head Bolt Price List, UNS N07718 Allen Bolt Price Per Kg, ASTM B637 Inconel 718 U Bolt Grade Chart