SMO 254 Bolt

Stainless Steel Bolt

UNS S31254 Flange Head Bolt, SMO 254 Hex Bolt, ASTM A479 SMO 254 Hex Head Bolt, ASME SA479 SMO 254 Stud Bolt, SMO 254 Eye Bolt, UNS S31254 Anchor Bolt, WNRF 1.4547 Allen Bolt, Din 1.4547 U Bolt.

What does a 254 SMO Bolt mean?

Austenitic 254 SMO bolts have better cracking and penetration corrosion resistance. Due to its high molybdenum, chromium, and nitrogen concentrations, 254 SMO is the best grade for industrial applications. In cases when 316L or 317L grade of stainless-steel fails, 254 SMO is frequently employed. In addition to being substantially more substantial than the standard austenitic grades, 254 SMO bolts have exceptional elasticity and tensile properties.

Properties of 254 SMO Bolts:

It is simple to produce and weld 254 SMO. It is built of robust, long-lasting SMO Grade 254 Hex Bolts. The exceptional strength values of 254 SMO bolts are permitted for usage up to 750°F by boilers and compressed vessels. Since this alloy does not respond to heat treatment, cold lowering is the preferred method for hardening it.

Hard work is required to increase the durability and strength of UNS S31254 Heavy Hex Bolts, but it is often tricky because of the rapid hardening rate. High levels of elasticity and impact resistance are features of these fasteners. These fasteners are used in saltwater and other settings with high chloride concentrations. The bolt guarantees excellent strength and exceptional toughness at cryogenic temperatures.

In situations with both low and high temperatures, it also possesses strong mechanical properties. The Din 1.4547 Anchor bolts are put through various tests, including positive material identification, hydraulic, biochemical, physical, radiology, macroscopic, microscopic, and ultrasound. Other tests, such as the intergranular corrosion test, the flattening test, the flaring test, the eddy current test, and the pitting resistance test, are accorded significant priority. The product becomes more robust as a result.

About SMO 254 Bolt

Advantages of using 254 SMO Bolts:

People may find Grade 254 SMO PTFE Bolts in various sectors, including chemical, pharmaceutical, and oil refining. The product is offered in different specifications, including wall thickness, to meet the needs of the consumers.

- Good strength about double that of 300 series of steel

- Elastic modulus and impact strength

- Good resistance to pitting and crevice corrosion

- Good susceptibility to strain corrosion cracking

- Good general corrosion resistance

- The lower the carbon content, the lower the danger of intermetallic compounds during heating.

Applications of using 254 SMO Bolts:

- In bleach-dependent sectors like pulp and paper,

- Seawater protection for offshore oil

- Saltwater applications like desalination

- Chemical and food processing equipment

- Combustion products cleaning and desulfurization scrubbers

- Gas cleaning and desulfurization systems

Specification Of SMO 254 Bolt

| Specifications | ASTM A 193 / ASME SA 193 and DIN, ISO ,JIS ,GB, IS, BS, ASTM and all International Standards |

| Size | M3 - M100 | 3/6″ - 4″ | Custom Sizes |

| Bolt Length | 3 mm - 200 mm | Custom Sizes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads Configuration | UNF, BSW, BSF, METRIC, UNC, or as required and ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Head | Hex, Square, Round, Hex flange, Flat, T-head & Triangular etc. |

| Neck type | Hex, Square, Triangular, Oval & Knurled etc. |

| Manufacturing Process | Passivation /plain, Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing. |

| Surface Coating | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Packing | IN BULK: carton, pallet, Small Boxes or customer request |

| Test Certificate | As per EN 10204 / 3.1 Manufacturer Test Certificate, PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Delivery time | Regular product : 7-15 days, Custom product : 2-4 weeks |

Equivalent Grades SMO 254 Bolt

| Standard | UNS | Werkstoff Nr. | EN | SS | AFNOR |

| 254 SMO | S31254 | 1.4547 | X1CrNiMoCuN20-18-7 | 2378 | Z1 CNDU 20.18.06AZ* |

Chemical Composition SMO 254 Bolt

| Grade | Ni | C | Mo | Mn | Si | Fe | Cu | S | P | Cr |

| SMO 254 | 17.5 – 18.5 | 0.02 max | 6 – 6.5 | 1 max | 0.8 max | – | 0.5 – 1 | 0.01 max | 0.03 max | 19.5 – 20.5 |

Mechanical Properties SMO 254 Bolt

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.0 g/cm3 | 1320-1390 ℃ | 300 | 650 | 35 % |

Dimensions Of SMO 254 Bolt

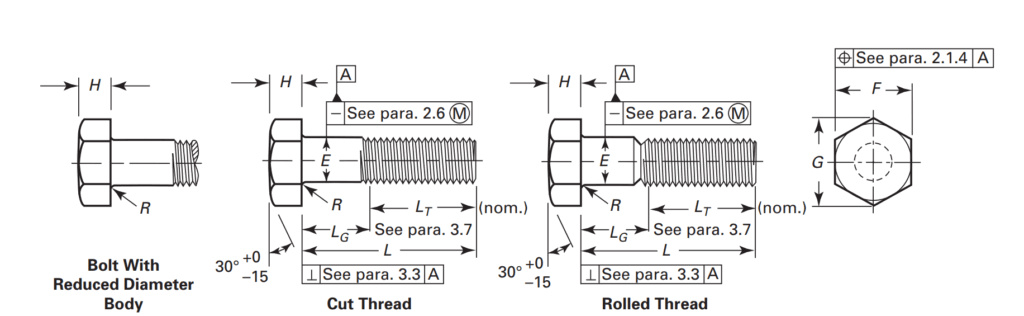

Stainless Steel Bolts Dimensions Chart :

| Nominal Size or Basic Product Diameter | Full-Size Body Diameter, E | Width Across Flats, F | Width Across Corners, G | Head Height, H Basic | Radius of Fillet, R | Nominal Thread Length for Bolt Lengths, LT |

|||||||||

| inch | mm | Max | Min | Basic inch | Max | Min | Max | Min | Basic inch | Max | Min | Max | Min | 6 in. and Shoter | Over 6 in. |

| 1⁄4 | 0.25 | 0.26 | 0.237 | 7⁄16 | 0.438 | 0.425 | 0.505 | 0.484 | 11⁄64 | 0.188 | 0.15 | 0.03 | 0.01 | 0.75 | 1 |

| 5⁄16 | 0.3125 | 0.324 | 0.298 | 1⁄2 | 0.5 | 0.484 | 0.577 | 0.552 | 7⁄32 | 0.235 | 0.195 | 0.03 | 0.01 | 0.875 | 1.125 |

| 3⁄8 | 0.375 | 0.388 | 0.36 | 9⁄16 | 0.562 | 0.544 | 0.65 | 0.62 | 1⁄4 | 0.268 | 0.226 | 0.03 | 0.01 | 1 | 1.25 |

| 7⁄16 | 0.4375 | 0.452 | 0.421 | 5⁄8 | 0.625 | 0.603 | 0.722 | 0.687 | 19⁄64 | 0.316 | 0.272 | 0.03 | 0.01 | 1.125 | 1.375 |

| 1⁄2 | 0.5 | 0.515 | 0.482 | 3⁄4 | 0.75 | 0.725 | 0.866 | 0.826 | 11⁄32 | 0.364 | 0.302 | 0.03 | 0.01 | 1.25 | 1.5 |

| 5⁄8 | 0.625 | 0.642 | 0.605 | 15⁄16 | 0.938 | 0.906 | 1.083 | 1.033 | 27⁄64 | 0.444 | 0.378 | 0.06 | 0.02 | 1.5 | 1.75 |

| 3⁄4 | 0.75 | 0.768 | 0.729 | 11⁄8 | 1.125 | 1.088 | 1.299 | 1.24 | 1⁄2 | 0.524 | 0.455 | 0.06 | 0.02 | 1.75 | 2 |

| 7⁄8 | 0.875 | 0.895 | 0.852 | 1 5⁄16 | 1.312 | 1.269 | 1.516 | 1.447 | 37⁄64 | 0.604 | 0.531 | 0.06 | 0.02 | 2 | 2.25 |

| 1 | 1 | 1.022 | 0.976 | 1 1⁄2 | 1.5 | 1.45 | 1.732 | 1.653 | 43⁄64 | 0.7 | 0.591 | 0.09 | 0.03 | 2.25 | 2.5 |

| 1 1⁄8 | 1.125 | 1.149 | 1.098 | 1 11⁄16 | 1.688 | 1.631 | 1.949 | 1.859 | 3⁄4 | 0.78 | 0.658 | 0.09 | 0.03 | 2.5 | 2.75 |

| 1 1⁄4 | 1.25 | 1.277 | 1.223 | 1 7⁄8 | 1.875 | 1.812 | 2.165 | 2.066 | 27⁄32 | 0.876 | 0.749 | 0.09 | 0.03 | 2.75 | 3 |

| 1 3⁄8 | 1.375 | 1.404 | 1.345 | 2 1⁄16 | 2.062 | 1.994 | 2.382 | 2.273 | 29⁄32 | 0.94 | 0.81 | 0.09 | 0.03 | 3 | 3.25 |

| 1 1⁄2 | 1.5 | 1.531 | 1.47 | 2 1⁄4 | 2.25 | 2.175 | 2.598 | 2.48 | 1 | 1.036 | 0.902 | 0.09 | 0.03 | 3.25 | 3.5 |

| 1 5⁄8 | 1.625 | 1.658 | 1.591 | 2 7⁄16 | 2.438 | 2.356 | 2.815 | 2.616 | 1 3⁄32 | 1.116 | 0.978 | 0.09 | 0.03 | 3.5 | 3.75 |

| 1 3⁄4 | 1.75 | 1.785 | 1.716 | 2 5⁄8 | 2.625 | 2.538 | 3.031 | 2.893 | 1 5⁄32 | 1.196 | 1.054 | 0.12 | 0.04 | 3.75 | 4 |

| 1 7⁄8 | 1.875 | 1.912 | 1.839 | 2 13⁄16 | 2.812 | 2.719 | 3.248 | 3.099 | 1 1⁄4 | 1.276 | 1.13 | 0.12 | 0.04 | 4 | 4.25 |

| 2 | 2 | 2.039 | 1.964 | 3 | 3 | 2.9 | 3.464 | 3.306 | 1 11⁄32 | 1.388 | 1.175 | 0.12 | 0.04 | 4.25 | 4.5 |

| 2 1⁄4 | 2.25 | 2.305 | 2.214 | 3 3⁄8 | 3.375 | 3.262 | 3.897 | 3.719 | 1 1⁄2 | 1.548 | 1.327 | 0.19 | 0.06 | 4.75 | 5 |

| 2 1⁄2 | 2.5 | 2.559 | 2.461 | 3 3⁄4 | 3.75 | 3.625 | 4.33 | 4.133 | 1 21⁄32 | 1.708 | 1.479 | 0.19 | 0.06 | 5.25 | 5.5 |

| 2 3⁄4 | 2.75 | 2.827 | 2.711 | 4 1⁄8 | 4.125 | 3.988 | 4.763 | 4.546 | 1 13⁄16 | 1.869 | 1.632 | 0.19 | 0.06 | 5.75 | 6 |

| 3 | 3 | 3.081 | 2.961 | 4 1⁄2 | 4.5 | 4.35 | 5.196 | 4.959 | 2 | 2.06 | 1.815 | 0.19 | 0.06 | 6.25 | 6.5 |

| 3 1⁄4 | 3.25 | 3.335 | 3.21 | 4 7⁄8 | 4.875 | 4.712 | 5.629 | 5.372 | 2 3⁄16 | 2.251 | 1.936 | 0.19 | 0.06 | 6.75 | 7 |

| 3 1⁄2 | 3.5 | 3.589 | 3.461 | 5 1⁄4 | 5.25 | 5.075 | 6.062 | 5.786 | 2 5⁄16 | 2.38 | 2.057 | 0.19 | 0.06 | 7.25 | 7.5 |

| 3 3⁄4 | 3.75 | 3.858 | 3.726 | 5 5⁄8 | 5.625 | 5.437 | 6.495 | 6.198 | 2 1⁄2 | 2.572 | 2.241 | 0.19 | 0.06 | 7.75 | 8 |

| 4 | 4 | 4.111 | 3.975 | 6 | 6 | 5.8 | 6.928 | 6.612 | 2 11⁄16 | 2.764 | 2.424 | 0.19 | 0.06 | 8.25 | 8.5 |

Different Types Of SMO 254 Bolt

Different Types Of Bolts

- 254 SS Hex Head Bolts

- SS 254 Allen Bolts

- 254 SMO Torx Bolts

- UNS S31254 12-Point Flange Bolts

- SS 254 Countersunk Bolts

- ASTM A479 SS 254 Hex Bolts

- DIN 1.4547 Carriage Bolts

- A2-70 SMO Bolts

- SMO 254 Bolts

- SS 254 Forged Hook Bolts

- Alloy 254 Flange Head Bolts

- ASTM A479 SMO 254 Allen Bolts

Application of SMO 254 Bolt

Testing of SMO 254 Bolt

Packing of SMO 254 Bolt

Destination Of SMO 254 Bolt

- City We Deliver

- Country We Export

- People Also Search